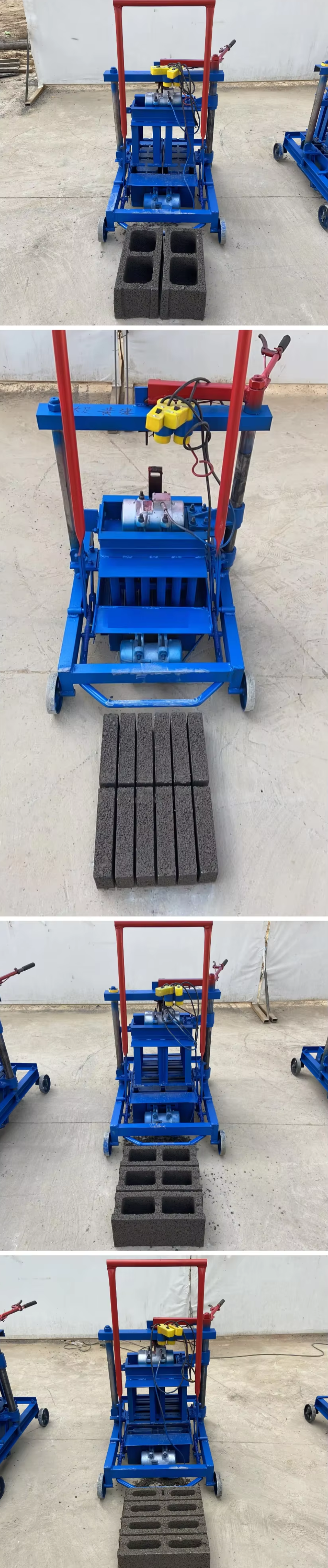

This brick-making machine is driven by a reliable diesel engine and is highly suitable for use in areas with limited or unstable power supply. It is operated manually and has a wide range of applications. It can produce bricks even in remote areas without relying on external power sources.

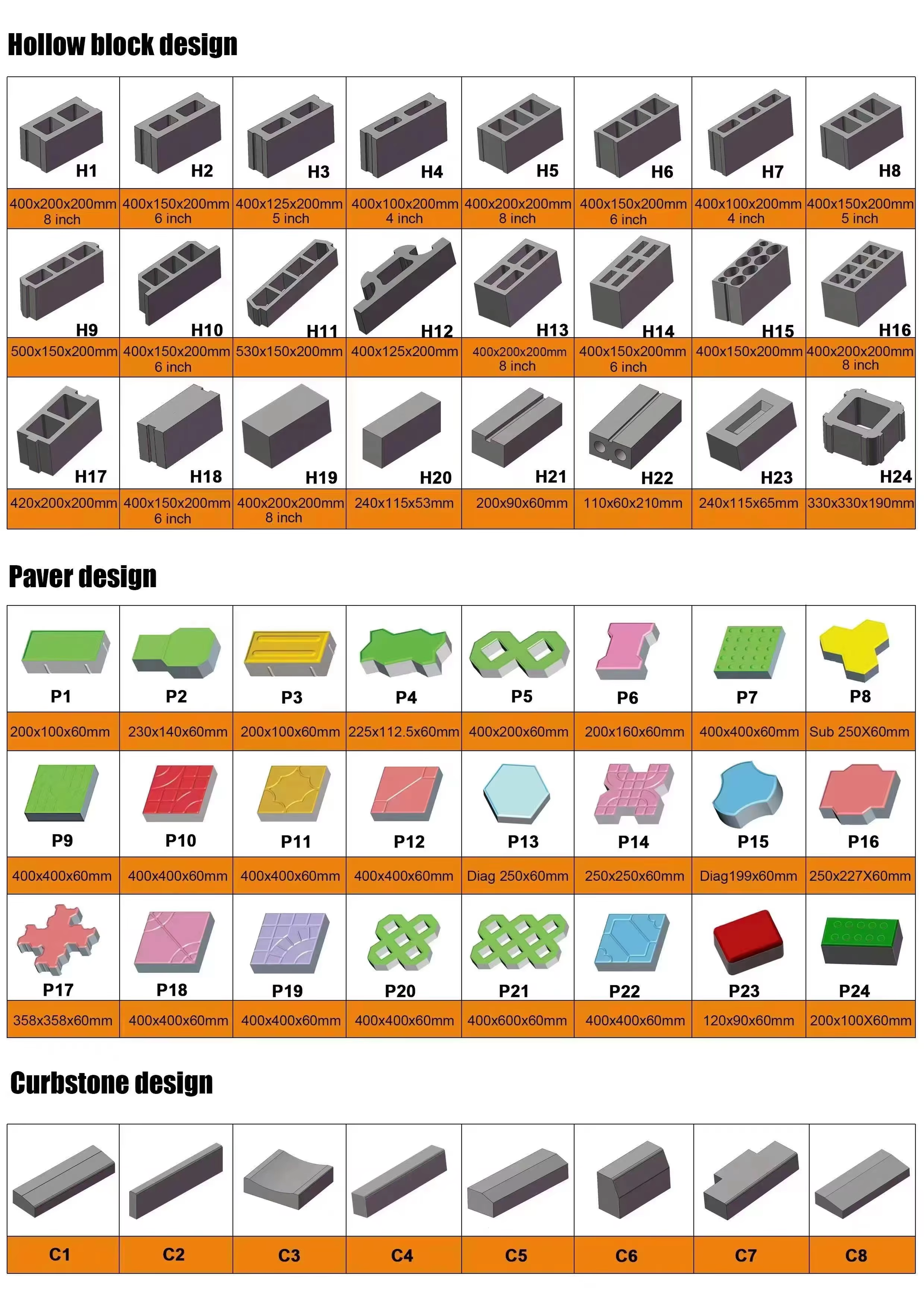

The cement brick-making machine is a piece of machinery used for manufacturing cement bricks, permeable bricks, curb stones, and other cement products. It mixes raw materials such as cement, sand, gravel, and coal ash, and then undergoes vibration and pressure molding to produce various building bricks. According to its structure and usage method, it is mainly divided into two types: mobile brick-making machines and fixed brick-making machines.

| Large size | 1100 * 800 * 1350 mm |

| Weight | 200kg |

| Tray size | Not necessary. |

| Total power | 1.5kw |

| Volt | 220V/380V/415V, 3-phase |

| Type | Hollow brick manufacturing machinery, paving brick manufacturing machinery, interlocking block forming machine, autoclaved aerated concrete block (AAC) | Brick Raw Materials | Clay, mud, coal gangue, shale, fly ash |

| Processing | Molding machinery | Voltage | 110V-220V-380V |

| Brick Size | 390*190*190mm, 400*100*200 mm, 400*120*200 mm. 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm | Country of Origin | Henan,China |

| Warranty Period | 1 year | Core Components | PLC, Engine, Motor |

| Weight (KG) | 200 kg | Automatic | None |

| Dimensions (L x W x H) | 800*1250*1400mm | Key Selling Points | Easy to operate |

| Machinery Test Report | Available | Video Factory Inspection | Available in 1000-750-1300 (L-W-H) mm |

| Type | 2-45 Inclined Pusher with Mixer | Machine Dimensions | 1000-750-1300(L-W-H) mm |

| Machine Weight | 200KG | Mechanical Voltage | 110V-220V-380V |

| Number of Operators | 1-2 | 400-200-200 bricks | Two bricks at a time, 600 bricks in eight hours |

| 400-150-200 Bricks | Three bricks at a time, 900 bricks in eight hours | 400-100-200 bricks | Four bricks at a time, 1200 bricks in eight hours |

The requirements for export wooden boxes are mainly to protect the goods during transportation and to comply with international trade and transportation standards. We will strictly adhere to the following points:

The export wooden boxes should use wood that has been treated against pests, and should meet international standards, such as treated wood.

The wooden boxes should be designed reasonably according to the size and weight of the goods, and should have sufficient structural strength and stability. There should be a firm connection between the bottom plate and the four walls, as well as appropriate internal support structures.

Important information should be marked on the wooden boxes, such as the product name, quantity, weight, contact information of the shipper and consignee, transportation marks and precautions.

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A : Our machines employ advanced technology. Moreover, we conduct strict supervision during the production process and ensure the quality of each finished product.

A : Generally, approximately 10-15 working days after receiving your deposit, this will also depend on your order.

A : We offer a 12-month warranty.

A : Automobile concrete brick-making machine, automobile hydraulic brick-making machine, free pallet automatic block forming machine,concrete, mixer, batching machine, stacker, Cuber, etc.

A : By changing the molds, it can manufacture all types of standard building blocks.

Contact With Us

If you have any questions please fell free to contact with us.