Best excavator for sale with High quality and competitive price.Our excavator used has Humanized design more comfortable.TOP excavator seller with Best after-sales.

Email: [email protected]

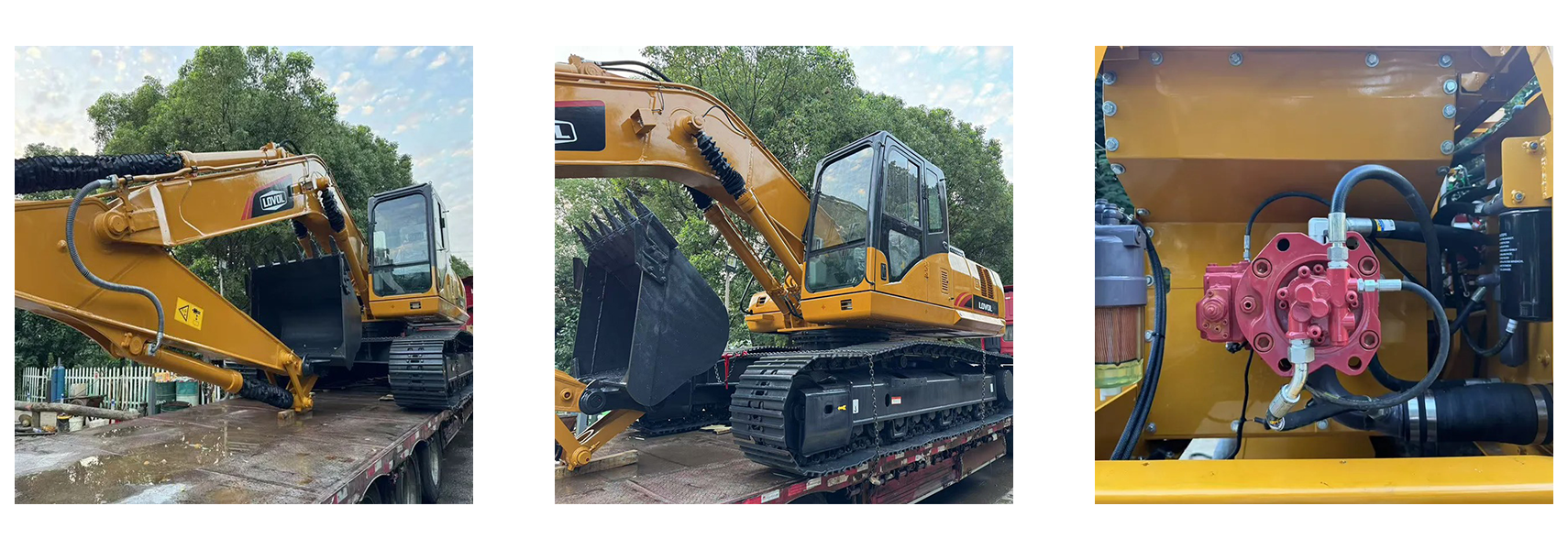

FR260 is a newly launched medium-sized excavator product by Lovol, primarily suitable for earthwork and stonework operations in conditions such as infrastructure construction, road building, building engineering, water conservancy projects, and mining sites.The Lovol Heavy Industry FR260 excavator has the advantages of high efficiency, strong strength, good stability, easy operation, good durability, and easy maintenance, making it suitable for various excavation work.

| Specification | ||

| Power | Traditional Power | |

| Bucket | backhoe | |

| Capacity (ton) | 26 | |

| Operating Weight (kg) | 26000 | |

| Bucket Capacity (m³) | 1.5 | |

| Performance | Swing Speed (rpm) | 11 |

| Swing Torque (Nm) | 85k | |

| Travel Speed (km/h) | 6 | |

| Gradeability (%) | 35 degrees | |

| Bucket Digging Force (kN) | 178 | |

| Stick Digging Force (kN) | 128 | |

| Maximum Traction Force (kN) | 200 | |

| Power System | Engine Model | Weichai WP7H |

| Rated Power (kW/rpm) | 190/2000 | |

| Maximum Torque (N.m) | 1000/1300-1500 | |

| Hydraulic System | Main Pump Max Flow (l/min) | 2X248 |

| Pilot Oil Line (MPa) | 3.9 | |

| Work Hydraulic Oil Line (MPa) | 37.3 | |

| Oil Capacity | Fuel Tank (L) | 420 |

| Hydraulic Oil Tank (L) | 206 | |

| Hydraulic System (L) | 280 | |

| Engine Oil Change Amount (L) | 17-25 | |

| Coolant (L) | 52 | |

| Main Dimensions | Transport Length (mm) | 10040 |

| Transport Width (mm) | 3180 | |

| Transport Height (mm) | 3322 | |

| Track Ground Length (mm) | 3840 | |

| Track Total Length (mm) | 4670 | |

| Track Pad Width (mm) | 600 | |

| Track Gauge (mm) | 2580 | |

| Counterweight Ground Clearance (mm) | 1106 | |

| Minimum Ground Clearance (mm) | 466 | |

| Minimum Swing Radius (mm) | 3390 | |

| Rear Swing Radius (mm) | 3060 | |

| Work Range | Maximum Excavation Radius (mm) | 10075 |

| Maximum Excavation Radius at Standstill (mm) | 9885 | |

| Maximum Digging Depth (mm) | 6645 | |

| Maximum Excavation Height (mm) | 10235 | |

| Maximum Dumping Height (mm) | 7270 | |

| Maximum Vertical Digging Depth (mm) | 6140 | |

Low Fuel-Consumption Engine

Equipped with original I SUZU turbo-charged engine which adopts mechanical high-pressure fuel pump and other technologies features strong power, low noise and low fuel consumption. Automatic idle function can reduce fuel consumption and noise dramatically.

Adopt original Kawasaki KC-MB-10 controller which adds automatic diagnostic function, the optimal control system makes rational match between the engine and main pump, making machines work efficiently with low fuel consumption.

The crushing mode is added to help operator use hydraulic hammer, thus get outperformance with low fuel consumption. The pipelines are also optimized through new design to reduce energy waste of hydraulic system.

The hydraulic pipelines adopt upgraded high-pressure hoses to avoid damage and oil leakage. Pilot oil filter is adopted which makes hydraulic system more reliable.

The advanced stress analysis technology and Q345 materials make whole structures more reliable.

The front and rear support of boom are made of cast steel which effectively reduces concentration of stress, key positions are also reinforced by welding strength plate, which makes arm more robust.

All the wiring harnesses adopt waterproof and dustproof connector, which has high security level and high reliability. Shut-down protection is added to reduce the failure possibility for electrical elements when power was cut off.

Equipped with spacious cab which provides operator large space to operate machine. The premium suspension seat with armrests is very comfortable and it can reduce the working fatigue dramatically. Big LCD screen is easy to read all data when working. Air conditioning can provide comfortable feeling in cab.

The proportional joystick delivers sensitivity, accuracy and smoothness in operation.

This joystick is specially designed to meet different operating conditions.

Intelligent control system is standard which could control diverse attachments such as bucket, hammer, scarifier and hydraulic scissors.

In order to reduce work fatigue and improve productivity, the noise inside of cab has been controlled to the lowest level. The cab is attached to the frame with buffer that dampens vibrations and sound levels to enhance operator comfort.

Add trouble code diagnostic and maintenance monitor functions which are convenient for operator to find the failure and do the routine maintenance on time.

The large engine hood enlarges maintenance space for operator to check and maintain the engine. The tool box is big with big opening angle which can put grease bucket and special tools easily. One key can open all locks of machine, it is very convenient for the operator.

All the filters are fixed at ground level position, it is very convenient to do routine maintenance. The maintenance interval is also extended to save time and cost.

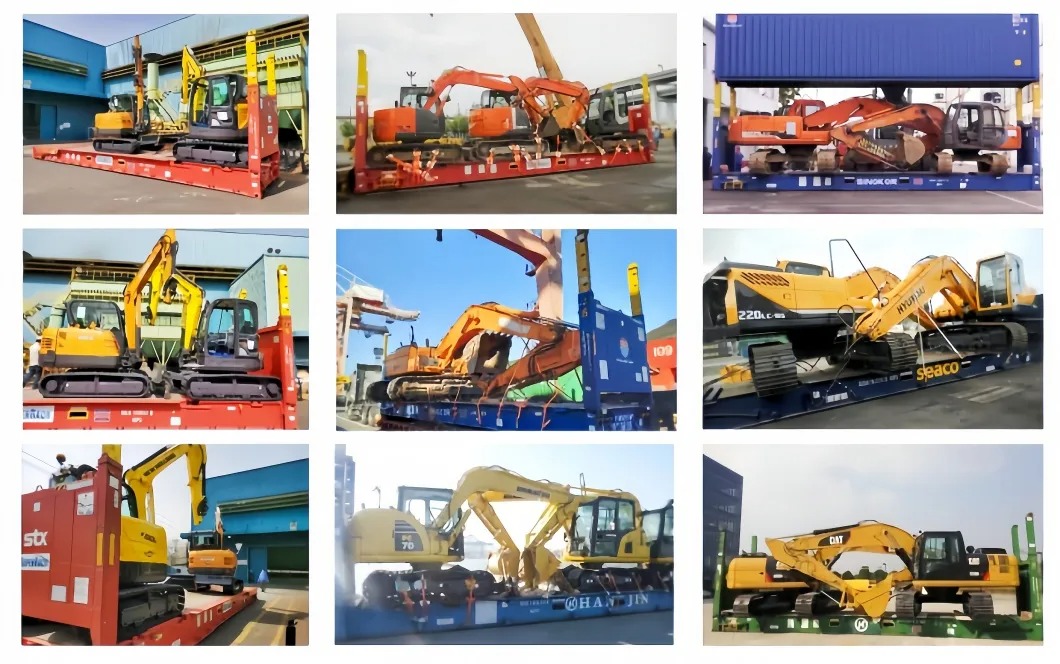

According to the product size and transportation scale, we can provide you with RORO, container, bulk carrier and other transportation methods.

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A: We will ship the goods within 3 to 7 days after receiving the payment. The exact time may vary depending on the distance.

A: Please inspect them on the spot when receiving the goods. If there is any damage, take photos immediately and contact us for assistance in handling the issue.

A: The engine, hydraulic system, etc. are all equipped with Liugong’s original factory products or designated brands.

A: The sales consultant will provide professional configuration suggestions based on your specific working conditions.

A: The whole machine is usually covered by warranty for 12 months or 2000 hours (whichever comes first). The specific period is as stated in the warranty manual.

A: After calling the service hotline, the engineer will usually contact and arrange the repair within 2 to 24 hours.

A: Basic operation and maintenance guidance will be provided upon delivery of the equipment, and further consultation is available afterwards.

For more details, kindly please contact us or send us inquiry, we’ll reply you within 8 hours. Hope we can reach a mutual success!

Our company will offer you the high quality products with a low price, quick delivery,and professional after-sale service.

Contact With Us

If you have any questions please fell free to contact with us.