The diesel concrete mixer pump integrates mixing and pumping functions, is compatible with both diesel and electric power, and is flexibly adaptable to various scenarios. It integrates a three-mode mixing system and a high-pressure hydraulic system, providing intelligent, precise, and efficient control. A single unit can complete on-site concrete production and delivery. Its compact structure and high mobility allow for continuous construction with just one operator, significantly reducing costs and improving efficiency. It is suitable for various engineering fields such as construction and bridges.

Email: [email protected]

The diesel concrete mixer pump is a multi-functional integrated machine that innovatively combines the functions of concrete mixing and concrete pumping in a single unit. This equipment can independently produce concrete and directly complete the pumping operation, completely solving the pain point in traditional construction where mixing and pumping required separate equipment.

| Items | Units | Parameters | |

| Whole performance of machine | Maximum theoretical concrete output (L/H.) | m3/h | 40 |

| Maximum concrete pumping pressure (H /L.) | MPa | 13 | |

| Concrete valve type | – | S Valve | |

| Concrete cylinder diameter × stroke length | mm | Φ160×1000 | |

| Hopper capacity×hopper height | L×mm | 450×1000 | |

| Outlet inner diameter | mm | Φ125 | |

| Delivering pipe inner diameter | mm | Φ100 | |

| Maximum aggregate diameter | mm | Pebble: 35 | |

| Gravel: 40 | |||

| Maximum delivering distance (vertical/horizontal) | m | 100/300 | |

| Lubrication system | – | Automatic electric lubrication | |

| High-low pressure conversion | – | No | |

| Remote control | – | Wireless remote control | |

| Power System | Diesel engine | – | R4105IZD(Weifang Huadong) or WP4.1D80E201/wp4g110e220(Weichai) |

| Rated power | kW | 66KW or 84kw(Weifang Huadong)72KW/82kw(Weichai) | |

| Rated speed | RPM | 1800 | |

| Rated fuel consumption | L/h | 12 | |

| Hydraulic system | Hydraulic system | – | Open circuit |

| Displacement of main oil pump | mL | 112 | |

| Pumping system pressure | MPa | 31 | |

| Mixing system pressure | MPa | 12 | |

| Hydraulic tank capacity | L | 160 | |

| Other Parameters | Dimensions: length×width×height | mm | 5200×2280×2900 |

| Host weight | kg | 4500 | |

| Total weight | kg | 6000 |

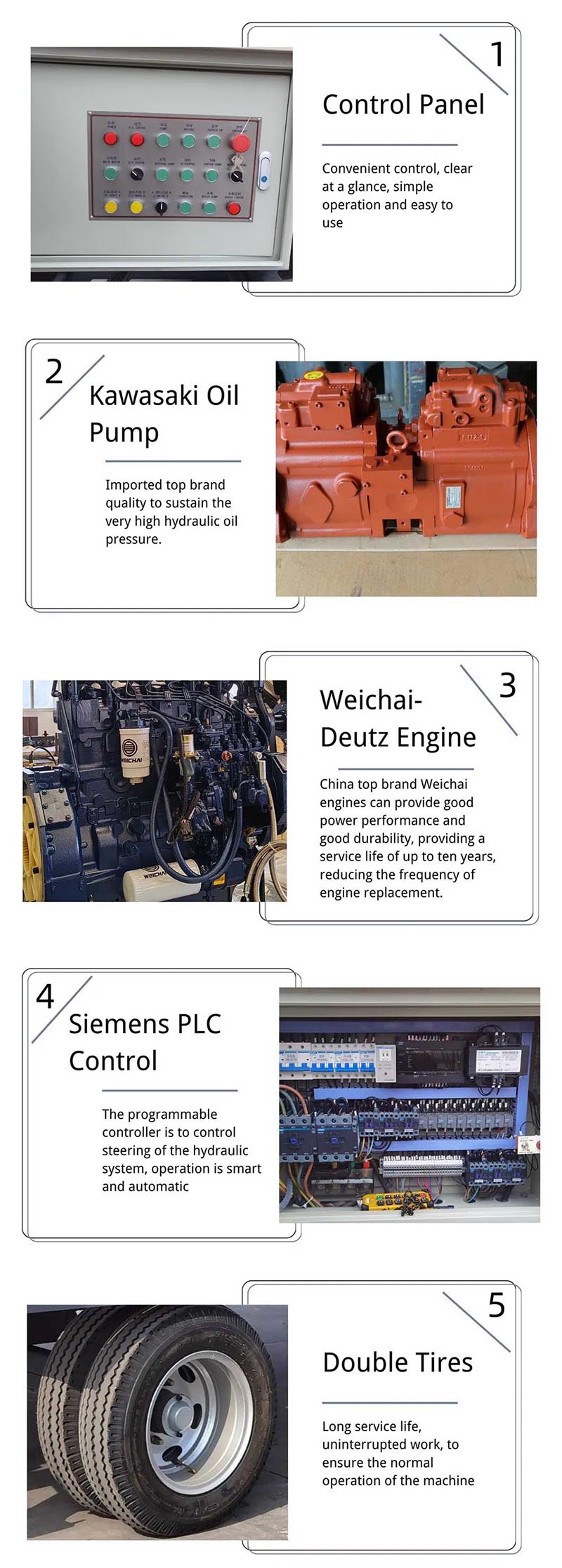

1. Mixing System

Supports three mainstream mixing modes: drum mixer, twin-shaft mixer, and planetary mixer. It can be flexibly configured according to project requirements to ensure the uniformity and production efficiency of concrete mixing.

2. Power System

Offers diesel-powered and electric-driven dual-version options, adapting to construction scenarios without power supply or in remote areas, demonstrating industry-leading power adaptability.

Contact With Us

If you have any questions please fell free to contact with us.