Efficient and flexible · Widely applied in small-diameter and deep drilling construction in civil engineering. The main hoist has a large lifting force, the steel wire rope rises and descends quickly, the hole formation has good verticality, and the construction efficiency is high. Specialized chassis · The telescopic and widened chassis specially designed for rotary drilling machines, with roller-type large-diameter slewing bearings, ensures high stability for deep-hole construction. Eco-friendly economy · Imported large-displacement electronically controlled fuel injection technology engines, with powerful performance. They adopt power optimization control technology, which can adjust power distribution in real time, ensuring quick response and higher fuel efficiency, thus being more energy-saving. High reliability · The mast adopts a box-type structure, with strong torsional and fatigue resistance capabilities; the sixth-generation drill pipe uses upgraded materials and is combined with an enhanced ring structure, resulting in an overall strength increase of 25%. It has strong drilling capabilities in strongly weathered rock layers.

Email: [email protected]

The multi-purpose drilling rig, as the name suggests, is a highly modular and configurable mobile drilling equipment designed to perform various types of drilling tasks. Unlike specialized drilling rigs (such as large oil drilling rigs, deep geothermal drilling rigs), it is not constructed for a single purpose. Instead, by replacing or adjusting its key components (such as drill pipes, drill bits, mud pumps, power heads, etc.), it can adapt to a wide range of geological conditions and engineering requirements.

The core design concept is “one machine for multiple uses”, aiming to provide flexibility for drilling contractors, engineering companies and exploration units to cope with diverse projects, thereby increasing equipment utilization and reducing overall investment and operating costs.

The LC65 is an innovative, multi-functional drilling rig designed specifically for small pile foundation applications in urban, industrial, civil, and municipal projects. It effectively overcomes the challenges of small-diameter, close-range, and confined space construction, achieving efficient, precise, and rapid operation in various complex geological conditions, including soft soil, backfill, sand, and moderately weathered rock.

Integrating a high-precision power head and modular attachments, this model ensures a balance between hole quality, construction speed, and equipment flexibility in small pile foundation construction (such as micropiles, root piles, and anchor bolts), making it an ideal solution for modern densely populated urban areas and small-scale infrastructure projects.

Economical and energy-saving with powerful output. Capable of high-efficiency drilling and soil dumping, handling holes as small as φ400mm.

Easy to transport without disassembly. Features a quick-switch low headroom mode for confined spaces and offers strong mobility with great climbing ability.

Long wire rope service life due to single-layer winding design, reducing wear and maintenance costs.

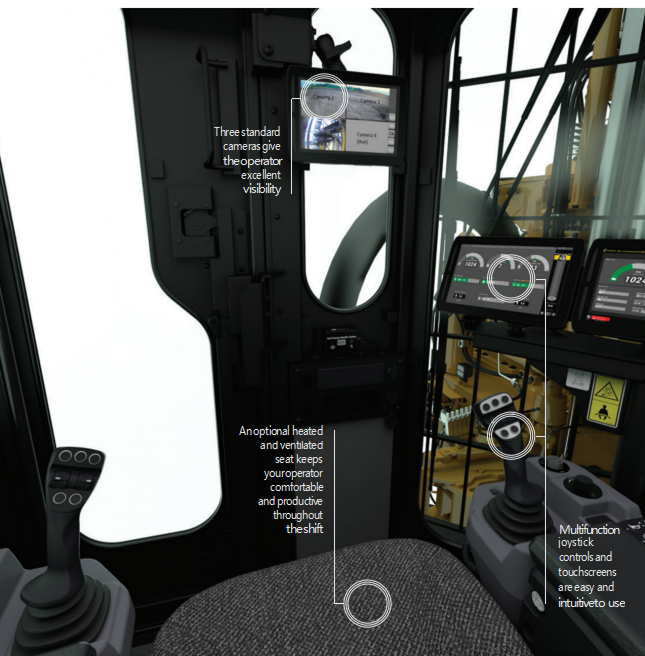

Spacious cab with air-suspension seat for reduced fatigue. Equipped with an intuitive HD touch display, quick-start buttons, and Bluetooth for an enhanced user experience.

| Main performances | Unit | Parameter | Remark |

| Pile | |||

| Max.drilling diameter | mm | 1100 | 400 |

| Max.drilling depth | m | 27/20 | |

| Low headroom drilling depth | m | 9 | |

| Rotary drive | |||

| Rated output torque | kN-m | 70 | |

| Rotation speed | rpm | 5~40 | |

| Crowd system | |||

| Crowd force | kN | 110 | |

| Line pull | kN | 120 | |

| Stroke | mm | 3000 | |

| Main winch | |||

| Lifting capacity | kN | 90 | |

| Wire rope diameter | mm | 20 | |

| Max.line speed | m/min | 80 | |

| Auxiliary winch | |||

| Lifting capacity | kN | 40 | |

| Wire rope diameter | mm | 14 | |

| Max.line speed | m/min | 75 | |

| Mastindination | |||

| Forward/backward | 。 | 5/90 | |

| Lateral | 。 | ±3 | |

| Main Chassis | |||

| Base engine | 1 | 4JJ1 | ISUZU |

| Engine power | kW/rpm | 84/2200 | |

| Exhaust emission | 1 | China Stage | |

| Engine displacement | L | 2.999 | |

| Extension width | mm | 2700 | |

| Track shoe width | mm | 600 | |

| Swing radius | mm | 3060 | |

| Overall machine | |||

| Overall height | mm | 12765 | |

| Operating weight | t | 23 | |

| Transport width | mm | 2700 | |

| Transport height | mm | 3410 | |

| Transport length | mm | 11560 |

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

Q: How automated is the drilling machine? How many people are needed for operation?

A: Equipped with an intelligent control system (with optional PLC interface), it supports automatic inclination adjustment, drilling pressure regulation and fault warning. The standard operation only requires 1-2 people and they can get started with basic training.

Q: Does the equipment have safety protection features?

A: It is equipped with overload protection, hydraulic locking, and emergency braking devices. The key components comply with ISO safety standards. Optional features include anti-collapse hole devices and remote emergency stop systems.

Q: How long does the consumable (such as drill bits) last? Is it easy to replace?

A: The drill bits are made of high-strength alloy steel and can last for an average of 800 to 1500 meters (depending on the geological conditions). They are equipped with a quick-change interface design, and the replacement process only takes 15 to 30 minutes.

Q: Can the machine be customized according to our specific requirements?

A: Customization services are available, including installing a mud circulation system, a casing drive device, and a customized trailer chassis, etc. Please provide specific requirements and our engineers will design a solution for you.

Q: Does the product meet international certification standards?

A: It has obtained CE and ISO9001 certifications, and some models comply with EPA Tier 3 emission standards. Localized compliance support can be provided for target markets (such as GCC, SONCAP, etc.).

Contact With Us

If you have any questions please fell free to contact with us.