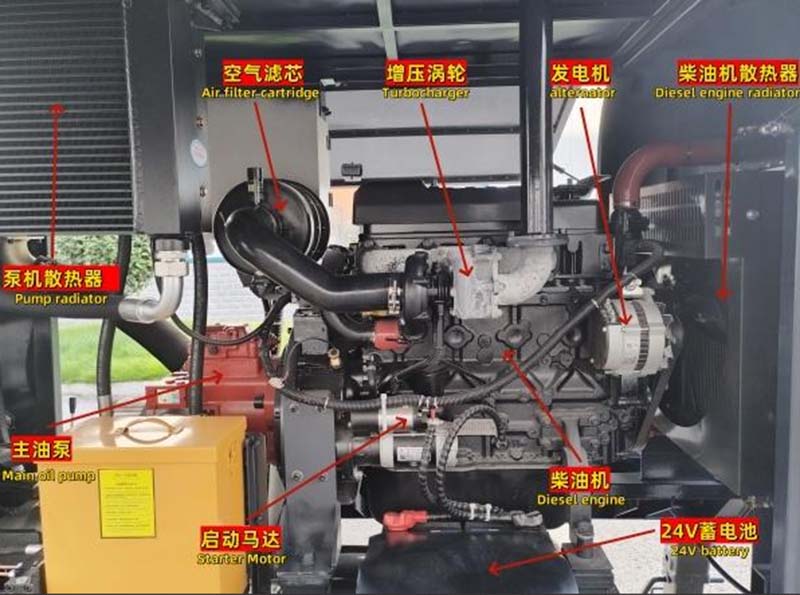

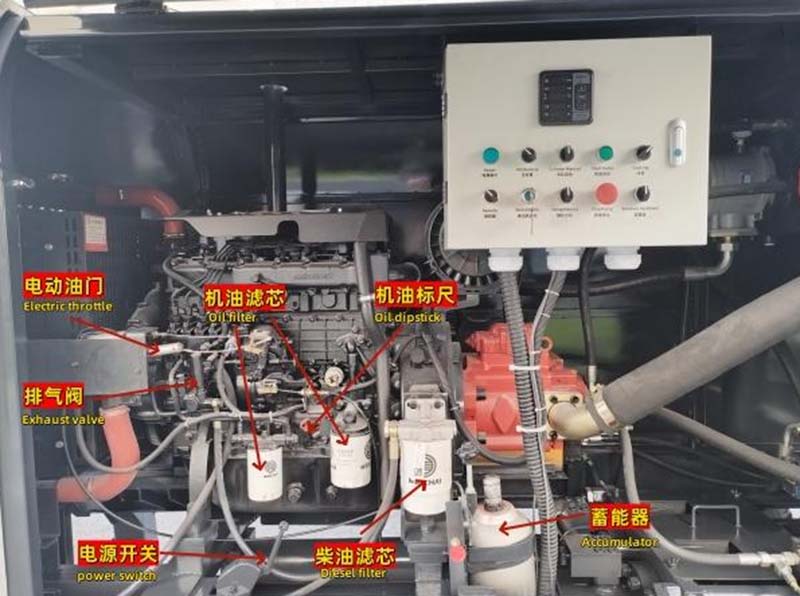

The Diesel Concrete Pump HBT50.10.92RS is a robust, mobile construction machine powered by a 62KW Yuchai diesel engine, designed for efficient concrete conveying in various job sites, especially where electricity is unavailable or unstable. The pump utilizes Korean-imported Kawasaki hydraulic pumps, China’s top-tier hydraulic valve groups, and imported polyurethane pistons for enhanced durability and anti-clogging performance.

Email: [email protected]

Diesel concrete transfer pump is a kind of mechanical equipment used to transport concrete. It uses a diesel engine as a power source, which has strong power and adaptability.

The diesel concrete transfer pump plays an important role in building construction, which can improve the efficiency and quality of concrete pouring and reduce the labor intensity.

Mixer Concrete Pump HBT50.10.92RS pumps standard concrete, the actual pumping vertical height is 40-50 meters (about 15 floors), the horizontal conveying distance is within 180 meters, the pressure is greater, and the conveying distance is farther.

| Serial Number | Parameter List Items | Unit | Technical Parameters |

| 1 | Maximum theoretical concrete conveying capacity | m³/h | 45 |

| 2 | Total power | KW | 62 |

| 3 | Rated speed | Rpm | 2200 |

| 4 | Maximum aggregate | mm | 40 |

| 5 | Outlet pressure | MPa | 8 |

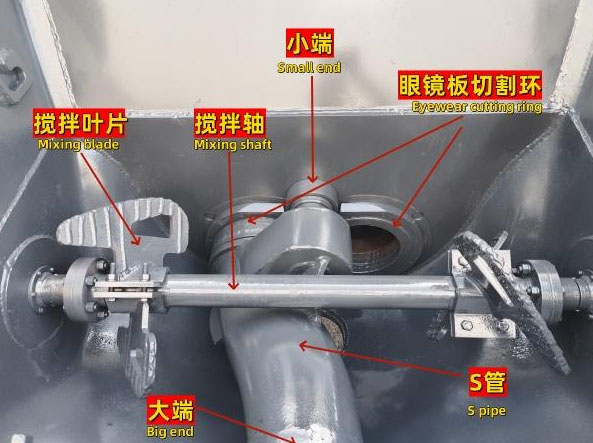

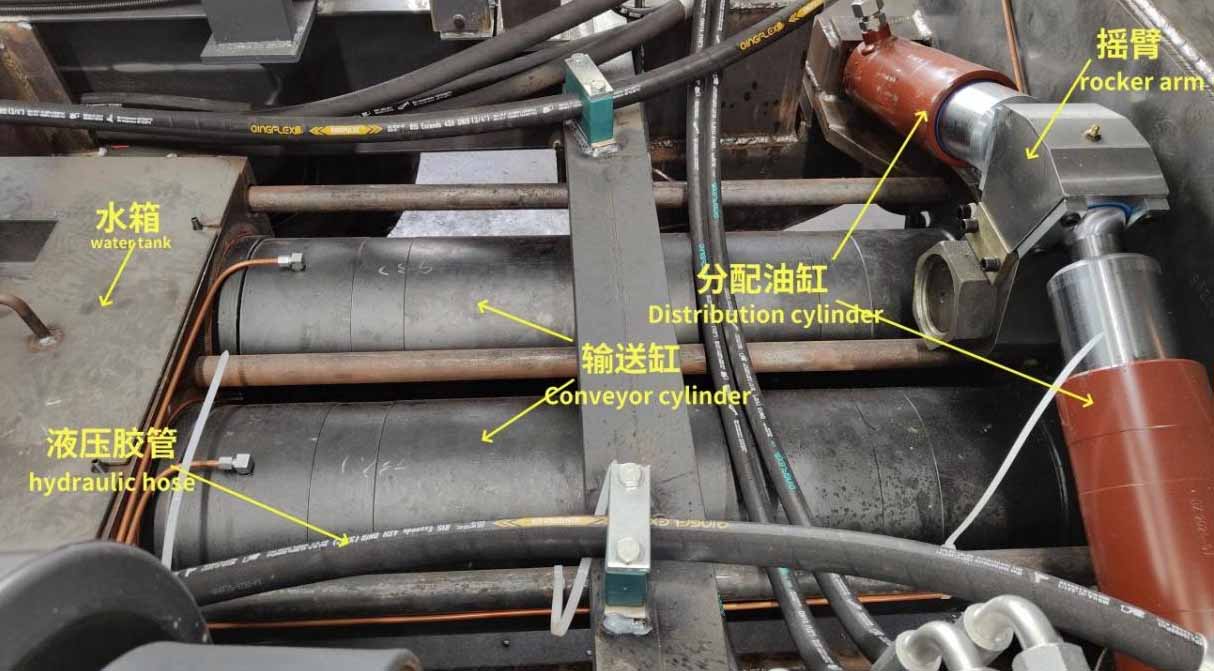

| 6 | Conveyor cylinder diameter | mm | 200 |

| 7 | The total length of the conveying cylinder | mm | 977 |

| 8 | Pumping hopper volume × loading height | m³×mm | 0.7×1200 |

| 9 | Conveyor pipe diameter | mm | φ125 |

| 10 | Concrete slump | mm | 160~220 |

| 11 | Dimensions | mm | 4500×1850×1750 |

| 12 | Total mass | KG | 4000 |

The integral frame is adopted, the structure is firmer, the hydraulic system of diesel engine and oil pump is built under the lifting hopper, the overall structure is more compact, and the machine volume becomes smaller, making the towing more convenient and safer.

Imported or domestic brand-name electrical components are used,with high sensitivity, good stability and low failure rate.

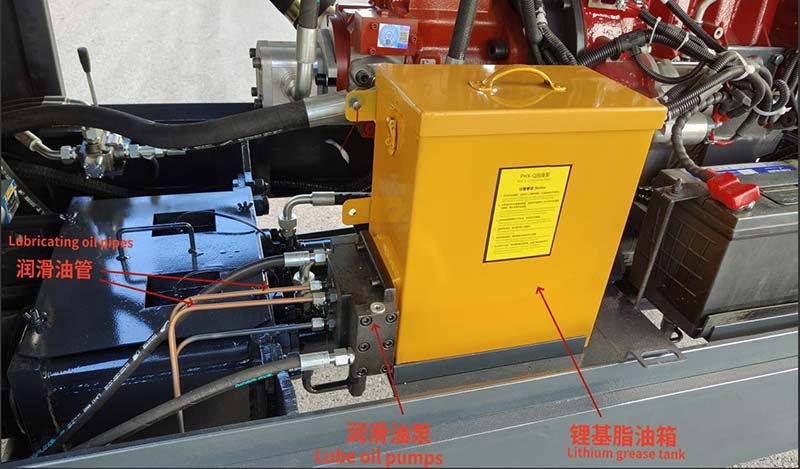

The lubrication system automatically lubricates, making operation more worry free and effortless.

Contact With Us

If you have any questions please fell free to contact with us.