Transverse milling machine integrates core advantages such as high efficiency, flexibility, robustness, and ease of maintenance. It is not only a powerful milling tool but also a professional solution dedicated to improving the efficiency and safety of large-scale section handling operations. Choosing our transverse milling machine means opting for a smarter, more reliable, and more economical method for large-section construction, helping you easily tackle various severe construction challenges.

Email: [email protected]

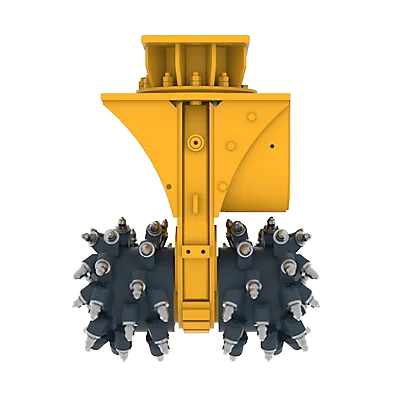

The transverse milling machine is a heavy-duty engineering equipment designed for surface treatment, contour shaping, and large-scale demolition of wide sections of hard materials like rock and concrete. Its core feature is that the rotation axis of the cutter head is perpendicular to the direction of the mechanical arm, enabling large-area, high-efficiency milling and excavation of the work surface. It overcomes the shortcomings of traditional blasting and pneumatic hammer operations in terms of safety, precision, and control ability, making it particularly suitable for demanding applications requiring precise section trimming on sidewalls, floors, and slopes.

| Parameter | ER 40x | ER 50x | ER 50 | ER 100x | ER 100 | ER 250x | ER 250 | ER 600 | ER 650 | ER 1500X | ER 1500XL | ER 1700 | ER 2000 | ER 2000X | ER 3000 | ER 4000 | ER 5500 |

| Suitable Excavator Weight (t) | 0.6-2 | 45660 | 45660 | 45723 | 45723 | 45884 | 45884 | 45948 | 15-25 | 30-50 | 35-50 | 35-55 | 50-70 | 55-75 | 70-125 | 70-125 | 70-125 |

| Chassis Weight Class (t) | 0.6-2 | 45660 | 45660 | 45723 | 45723 | 45884 | 45884 | 45948 | 15-28 | 20-40 | 35-55 | 35-55 | 50-70 | 55-75 | 70-125 | 70-125 | 70-125 |

| Self Weight (kg) | 110 | 170 | 200 | 330 | 350 | 520 | 570 | 900 | 1200 | 2000 | 2700 | 4000 | 5500 | 7000 | 4000 | 5500 | 7000 |

| Product Weight (kg) | 90 | 130 | 160 | 290 | 310 | 450 | 500 | 820 | 1000 | 1750 | 1850 | 2200 | 2600 | 2400 | 3500 | 4800 | 6000 |

| Optimal Oil Flow (L/min) | 17-22 | 25-38 | 25-38 | 52-62 | 41-62 | 60-85 | 60-85 | 120-150 | 140-190 | 205-300 | 205-300 | 290-360 | 300-390 | 300-390 | 350-450 | 500-750 | 700-950 |

| Rated Power (kW) | 13 | 18 | 18 | 30 | 30 | 45 | 45 | 65 | 80 | 120 | 120 | 120 | 160 | 160 | 200 | 280 | 400 |

| Rotation Speed (rpm) | 130 | 150 | 150 | 115 | 115 | 90 | 90 | 80 | 80 | 75 | 75 | 72 | 65 | 65 | 53 | 50 | 48 |

| Max. Torque @350 bar (Nm) | 960 | 1420 | 1420 | 3000 | 3000 | 5200 | 5200 | 10100 | 10100 | 23400 | 23400 | 27900 | 31500 | 31500 | 46800 | 90000 | 111500 |

| Max. Cutting Force @350 bar (N) | 8530 | 12620 | 11850 | 16200 | 16200 | 26000 | 26000 | 35100 | 42400 | 65000 | 65000 | 77500 | 87500 | 87500 | 116300 | 200000 | 242400 |

| Cutter Shaft Diameter (mm) | 114 | 11.4 | 15 | 20 | 20 | 20 | 22 | 25 | 30 | 30 | 30 | 30 | 38 | 38 | 38 | 38 | 38 |

| Number of Cutters | 40 | 40 | 56 | 44 | 64 | 44 | 44 | 48 | 44 | 44 | 48 | 56 | 56 | 56 | 64 | 78 | 68 |

Contact With Us

If you have any questions please fell free to contact with us.