Using dedicated rotating supports ensures stable performance. The frame is made of imported HARDOX400 sheet material, featuring double-layer wear-resistant protection, high strength and long service life. For concrete structures, a one-time disassembly process is more efficient.

Email: [email protected]

It is mainly used for demolition and separation of reinforced concrete and other projects. The serrated teeth are made in special shapes to firmly fix the concrete blocks, wedge them in and crush them, so as to facilitate rapid crushing. There is a steel bar cutter on the inner side, which can cut the exposed steel bars while crushing the concrete. It can directly dismantle buildings, houses, etc., making the crushing operation more efficient. The jaws of the crocodile clamp are wide and have a large gripping force, and are suitable for various tonnage excavators.

The hydraulic crushing pliers are composed of an upper frame, an upper jaw, an outer shell and an oil cylinder. The upper jaw is made up of jaw teeth and blades. The external hydraulic system provides oil pressure to the hydraulic cylinder, enabling the upper jaw and the fixed jaw of the hydraulic crushing pliers to open and close, thus achieving the effect of crushing objects.

The features of the crushing pliers produced by LICH

Carry out secondary crushing of the concrete and separate the reinforcing bars from the concrete.

②Unique jaw structure design, with double-layer wear-resistant protection and imported HARD OX 400 steel plate.

③ This structure adopts load optimization design, taking into account the opening size and crushing force in a balanced manner.

Utilizing special steel with high ductility and high tensile strength, this ensures the firm structure of the equipment and a long service life.

Equipped with hydraulic valves and large hydraulic cylinders, it enhances the piston power, improves the efficiency of hydraulic oil utilization, and provides powerful crushing and shearing capabilities.

Inspired by the principle of jaw crushers, it features a wide opening and a large working area, making the operation simple and the crushing efficiency high.

Two types are available – rotational and fixed. Customers can choose the one that suits their actual usage scenarios.

Suitable for the crushing and recycling processing of construction waste such as cement and steel bars. It is a high-quality equipment in the field of resource recycling.

| LC range | LC 350 | LC 750 | LC 950 | LC 2500 | LC 4500 | LC 5500 | LC 7500 | |

| Carrier weight class 1 | t | 2–6 | 6–13 | 11–17 | 20–35 | 40–55 | 50–65 | 70–85 |

| Service weight 2 | kg | 320 | 730 | 940 | 2,600 | 4,650 | 5,500 | 7,400 |

| Product weight | kg | 290 | 617 | 794 | 2,370 | 4,295 | 5,080 | 6,750 |

| A | mm | 907 | 1,374 | 1,700 | 2,260 | 2,650 | 2,950 | 3,300 |

| B | mm | 380 | 480 | 680 | 1,100 | 1,400 | 1,600 | 1,800 |

| C | mm | 219 | 269 | 324 | 750 | 810 | 1,060 | 1,120 |

| D | mm | 90 | 140 | 140 | 240 | 280 | 350 | 350 |

| F1 | t | 199 | 236 | 312 | 360 | 400 | 690 | 960 |

| F2 | t | 40 | 45 | 55 | 100 | 130 | 150 | 190 |

| Cycle time (opening/closing) 3 | sec | 3.8/3.0 | 3.4/2.6 | 5.8/5.0 | 3.8/2.8 | 3.6/2.6 | 4.1/3.5 | 4.8/4.7 |

| Oil flow rate (opening & closing) | l/min | 50–90 | 90–180 | 90–180 | 250 | 300–400 | 350–450 | 550 |

| Max. operating pressure (opening & closing) | bar | 300 | 350 | 350 | 350 | 350 | 350 | 350 |

| Oil flow rate (rotation) | l/min | 5–10 | 20–25 | 20–25 | 35–50 | 50 | 50 | 50 |

| Max. operating pressure (rotation) | bar | 170 | 210 | 210 | 170 | 115 | 115 | 115 |

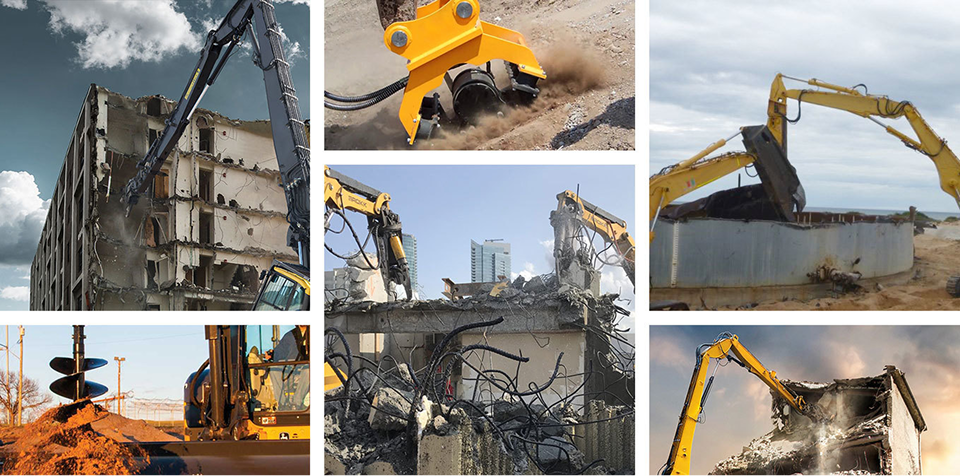

●Building demolition: Applicable to the layer-by-layer precise dismantling of high-rise buildings, factories, bridges, etc. in urban areas, which are made of reinforced concrete. It can effectively separate the concrete and the steel bars, reducing dust and noise pollution. It is especially suitable for construction sites in urban areas or near sensitive buildings where strict vibration restrictions are required. Static

●Demolition: In partial demolition projects where the main structure or surrounding facilities need to be protected (such as subway station renovations or machine room expansions), precise crushing can be carried out to avoid the structural damage caused by impact-based demolition.

●Road and bridge maintenance: Used for crushing old bridge decks, curb stones, concrete roadbeds and guardrails.

●Underground engineering: During the construction of subways, tunnels, and pipe galleries, the existing concrete supports or obstacles are removed.

●Municipal facility renewal: Demolition of old infrastructure, such as concrete foundation piles, water towers, chimneys, etc.

●At disaster sites such as earthquakes and explosions: Quickly and safely break down large components like collapsed concrete floor slabs, beams, and columns, to create rescue channels and avoid the risk of secondary collapses.

●Steel mills, foundries: Scrap from steel tundishes, molten iron tanks, slag, etc. – metallurgical waste.

Ship and vehicle dismantling: Used for dismantling large metal structures such as ship hulls and vehicle frames.

●Resource Recycling Center: Efficiently processes construction waste, completely separates concrete blocks from the internal reinforcing bars, and realizes the resourceful reuse of construction waste.

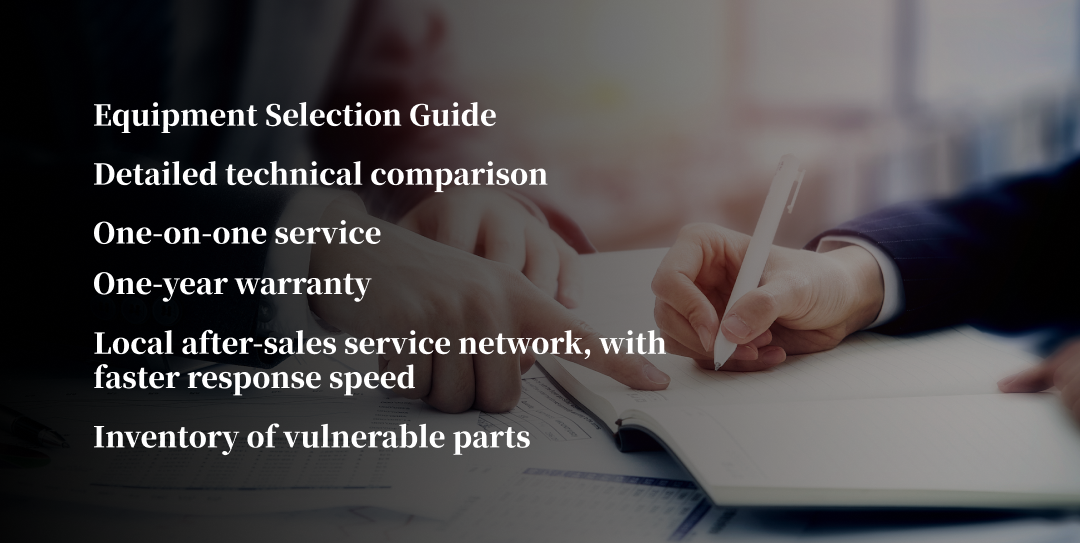

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A : Yes, we are a professional accessory manufacturer. We make accessories based on the size of your excavator bucket.

A : Sure, we can offer OEM and ODM services.

A : Our attachments are packed in standard export wooden boxes.

A : Usually it is 15 days depending on the quantity of the order. Due to the sudden increase in orders, please confirm the delivery time with the customer service staff.

Contact With Us

If you have any questions please fell free to contact with us.