It has the advantages of flexibility, wide operational range and strong adaptability to the site. According to different types of goods and operational requirements, it can quickly replace various attachments such as forks, lifting devices, platforms, etc., to achieve load-bearing elevated operations and transportation of goods of different shapes, sizes and weights, significantly improving the efficiency of urban infrastructure construction.

Email: [email protected]

Comfortable control console – The Lich crane is equipped with a spacious control console, featuring standard configurations such as an adjustable steering wheel, dual charging ports, cup holders, etc., as well as optional configurations like a closed cab with air conditioning and top sunshade curtains, all of which can provide an excellent comfortable experience during operation.

It combines the lifting capacity of a forklift with the extended operation range of a crane.

This unique design makes it indispensable in various industries such as architecture, agriculture, and event setup – anywhere where precise lifting, moving or placement of heavy objects is required.

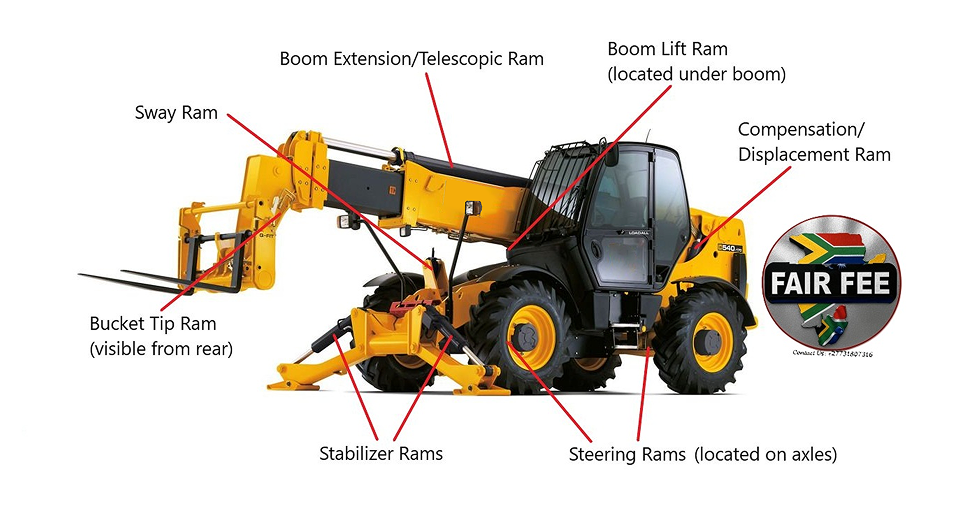

Extension arm: Unlike standard forklifts that can only be lifted vertically upwards, the extension arm of an extension arm forklift can be extended upwards, outward, or even at a certain angle – sometimes reaching over 50 feet.

Widely used attachments:

From pallet forks to buckets, boom arms, and working platforms, this machine can adapt to countless tasks.

Performance on rough terrain:

The extension arm forklift is stable and usually equipped with outriggers, enabling it to easily handle uneven outdoor surfaces.

Safety and load management:

Modern models include load charts and sensor systems to prevent tipping and ensure safe operation, even when extended.

In short, the extension arm forklift is like the “Swiss Army knife” of forklifts – small in size, suitable for narrow spaces, but powerful and adaptable, capable of replacing multiple machines.

For those challenging tasks that require pushing the boundaries, the telescopic boom truck can provide the range, power and flexibility needed to complete the job.

Multifunctionality and operational flexibility:

The quick replacement of attachments enables the off-road telescopic boom forklift to perform the tasks of a forklift, crane, and loader on a single machine.

Enhanced efficiency and cost savings:

The telescopic boom forklift simplifies the workflow by handling multiple tasks on a single machine and precisely placing materials, thereby saving time, labor, and equipment costs.

Improved safety:

Stabilizers and load monitoring systems (such as LSI) ensure safety when operating at heights or on uneven terrain.

Adaptability to challenging environments:

The telescopic boom forklift utilizes stabilizers and telescopic arms to navigate uneven terrains, enabling the precise placement of goods above obstacles that standard forklifts cannot reach.

Safety

The Load Stability Indicator (LSI) system can provide visual and auditory alerts to the operator regarding the stability of the machine’s operation, enabling you to operate with greater confidence.

Operational simplicity

The operation is smooth and predictable through the pilot-controlled joystick.

Extended maintenance cycle

Maintenance becomes effortless and convenient, such as 500-hour lubrication intervals, 500-hour boom maintenance, 3000-hour hydraulic oil, 6000-hour long-lasting coolant, and engine idle shutdown functions.

| Power (kilowatts) | 120 horsepower (89) |

| Maximum driving speed (kilometers per hour) | 22.8 miles per hour (36.7 miles per hour) |

| Turning radius (meters) | 12’2″ (3.7) |

| Lifting capacity (kilograms) | 11,000 pounds (4990) |

| Manufacturer | Cummins |

| Model | 3.8-liter QSF Grade 4 |

| Power (kilowatts) | 120 horsepower (89) |

| Maximum traveling speed (kilometers per hour) | 22.8 miles per hour (36.7 miles per hour) |

| Pump type | Open center double joint |

| Total flow rate (liters per minute) | 43 gallons per minute (162.8) |

| Main relief pressure | 3,000 psi (207) |

| Auxiliary relief pressure | 2,500 psi (172) |

| Hydraulic storage tank capacity (liters) | 45 gallons (170) |

● High-rise material delivery: Transport bricks, mortar, doors and windows, prefabricated components, etc. directly to the construction sites on the second floor, third floor or higher floors. Operators can be in a safe position downstairs and, by extending the boom, precisely deliver the materials to the hands of the workers or on the balconies and floor slabs without relying on tower cranes. The efficiency is extremely high.

● Roof work: Transport waterproof materials, insulation boards or lightweight steel structures to the roof. The boom can easily cross obstacles and directly place the materials at the designated positions on the roof.

● Indoor and outdoor material handling and stacking: Transport heavy materials such as steel pipes, formworks, cable reels, etc. within the construction site and stack them efficiently in the storage area.

● Hay and feed handling: Transport and stack huge round or square hay bales. With grab equipment, it is easy to grasp and feed the feed.

● Slaughterhouse cleaning: Transporting fertilizers and bedding materials, cleaning and maintaining the livestock sheds.

● Equipment maintenance and installation: Used for repairing tall barns, installing ventilation equipment, and loading and unloading agricultural supplies.

● Field auxiliary operations: Transporting fences, water pipes or small agricultural equipment across the fields.

● Log Handling: Utilize specialized wood grabs or forks to safely and efficiently transport, stack, and load/unload logs.

● Sawmill operation: Moving planks, boards and wood chips within the sawmill.

● Forest clearing: Assist in removing broken trees and branches from the forest area.

● Although indoor warehouses mostly use traditional forklifts, in the following scenarios, telescopic boom forklifts have obvious advantages:

● Container handling: When the goods inside the container are piled up deeply or need to be stacked at a higher position, the telescopic arm can extend into the deep part of the container for operation, or be raised to the second or third layer.

● Outdoor storage area: In unhardened or uneven open-air storage areas (such as steel markets, stone markets, and wood markets), handling and stacking various irregular or heavy goods.

Railway freight yard: Handling goods on both sides of the tracks.

● Tree planting and maintenance: Transporting large trees, hoisting trees for planting, and being able to lift workers to the tree canopy for pruning.

● Street lamp and traffic signal maintenance: As a mobile aerial work vehicle, it is responsible for repairing street and highway-side street lamps, traffic signals, and signs.

● Municipal facilities installation: Installation of park benches, bus stops, sports stadium seats, etc.

● Emergency rescue: At flood or disaster sites, it is used for transporting sandbags, rescue supplies, or clearing obstacles.

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A: The key feature is the extendable boom. Ordinary forklifts mainly operate on flat ground and handle stacked goods; this one can expand its working range, enabling three-dimensional operations over long distances and at high drops, and it also has strong off-road capabilities.

A: It is versatile and can be used in multiple ways by changing the attachments.

Stacker (fork)

Blasting (bucket)

Simple lifting (hook)

High-altitude work (work platform)

And including drilling, material grasping, etc.

A: It is suitable for complex and rugged outdoor areas:

Construction site (delivering materials to upper floors, roof work)

Agriculture (Transportation of Feed Materials)

Logistics storage yard (for loading and unloading containers)

Municipal maintenance (street lights, trees)

Industrial and mining auxiliary operations.

A: One machine can perform the tasks of forklifts, cranes, and elevated platforms, reducing the time for equipment scheduling and waiting. It is particularly suitable for on-site situations with variable tasks and limited space.

A: It’s slightly more complex than that of traditional forklifts. Regular professional maintenance is required, with the key points being the telescopic arm hydraulic system and safety devices.

Contact With Us

If you have any questions please fell free to contact with us.