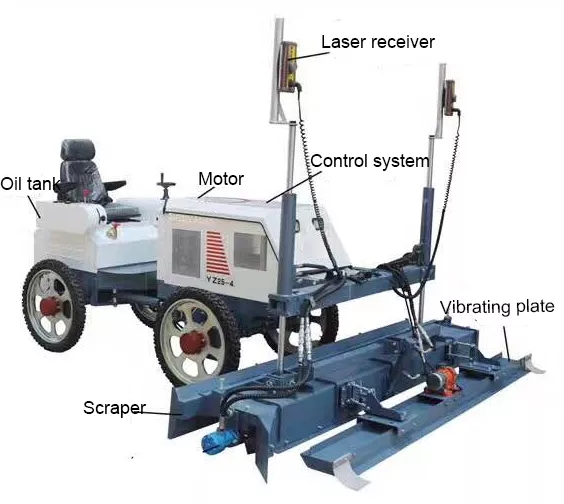

Our comprehensive product line of laser concrete machine includes agile two-wheel models, efficient four-wheel ride-on machines, and more powerful Max series models. A key advantage lies in their integration of internationally top-tier components—such as laser control systems from Danfoss (USA) and Mitsubishi (Japan), and engines from Honda and Briggs & Stratton—guaranteeing exceptional leveling precision for flat surfaces, slopes, and 3D dual-slope profiles, alongside high operational efficiency exceeding 200㎡ per hour. The nimble two-wheel model is ideal for confined spaces, while the four-wheel models offer advanced automation features like intelligent cruise control and real-time monitoring, significantly boosting efficiency and quality for large-area projects. This makes them the perfect choice for industrial flooring, warehouse logistics, and similar applications.

Email: [email protected]

Laser screed machines utilize laser measurement and control technology to automate the processes of concrete placement, vibration, and leveling. This not only significantly enhances construction efficiency but also ensures the achievement of exceptional surface flatness and strength, fundamentally addressing common issues like dusting and hollowing that often occur with traditional methods.Our range of high-performance laser screed models is designed to meet the specific requirements of projects of varying scales and under different site conditions. Whether for large-area applications or work in confined spaces, each of our machines is built to deliver maximum value on your job site.

| Engine | Jialing/Honda engine (manual/electric start) | Leveling thickness | Standard 680 tire 50-250mm/optional 980 tire 50-400mm |

| Power | 3.0KW | Exciting force | 2000N |

| Fuel volume | 17L(18 hours for construction) | Vibration motor speed | 3600rpm |

| Fuel consumption | 0.8-1.3L/h | Travel drive | Servo drive motor |

| Laser emission system | Swiss Leica transmitter/Japanese Topcon transmitter/Shuangpo transmitter | Walking mode | Automatic travel of electric control servo system |

| Laser receiving system | Swiss Leicareceiver/German Komec receiver | Walking speed | 0-28m/min |

| Laser control system | Japanese Mitsubishi/American Danfoss laser control system | Working speed | 4m-20m/min |

| Control effect of laser system | Plane,slope or double slope(3D) | Tail wheel control mode | Manual lifting |

| Laser system control mode | Automatic control oflaser micro-system to realize automatic leveling | Travel tire | Solid anti-skid and stab-resistant narrow tire/optional (inflatable wide tire) |

| Suspension mode | Flat head independent suspension system (can maintain fuselage balance in complex engineering) | Fuselage size | 3200x2700x1120mm |

| Vibration plate width | 2525mm | Fuselage weight | 260kg |

| Engine | Hua Ang custom engine | Leveling thickness | 680 tires 50-300 mm |

| Power | 22KW/30 HP | Exciting force | 2000N |

| Oil volume | 1.8L | Vibration motor speed | 3600rpm |

| Gasoline capacity | 37L | Travel drive | Low-speed high-torque reducer+hydraulic drive motor |

| Fuel consumption | 3-4L/h | Intelligent travel control system | One-button cruise control |

| Laser emission system | Double slope transmitter/Japanese Topcontransmitter/Swiss Leica transmitter | Walking speed | 0-55m/min |

| Laser receiving system | German CosmiQue /Leica Ms720 Receiver | Working speed | 4m-20m/min(adjustable speed) |

| Laser control system | Danfoss Laser Control System | Paving method | Hydraulic auger paving |

| Control effect of laser system | Plane, slope or double slope(3D) | Travel tire | Solid anti-skid and stab-resistant narrow tire |

| Laser system control mode | Automatic controloflaser micro-systemto realize automatic leveling | Machine size | 3250x2850x1320mm |

| Suspension mode | Fixed | Machine weight | 900kg |

| Vibration plate width | 2525mm/2955mm |

| Engine | Briggs Stratton engine imported from the USA | Leveling thickness | 680 tires 50-300 mm |

| Power | 25.73KW/35HP | Exciting force | 3000N |

| Oil volume | 2.3L | Vibration motor speed | 4000rpm |

| Gasoline capacity | 45L | Travel drive | Planetary reducer |

| Fuel consumption | 4-7L/h | Intelligent travel control system | One-button cruise control |

| Laser emission system | Double slope transmitter/Japanese Topcontransmitter/Swiss Leica transmitter | Walking speed | 0-60m/min |

| Laser receiving system | German CosmiQue /Leica Ms720 Receiver | Working speed | 3m-30m/min(adjustable speed) |

| Laser control system | Danfoss Laser Control System | Paving method | Hydraulic auger paving |

| Control effect of laser system | Plane, slope or double slope(3D) | Travel tire | Solid anti-skid and stab-resistant narrow tire |

| Laser system control mode | Automatic controloflaser micro-systemto realize automatic leveling | Machine size | 3500x3300x1700mm |

| Suspension mode | Fixed | Machine weight | 1100kg |

| Vibration plate width | 2955mm |

Contact With Us

If you have any questions please fell free to contact with us.