LICH's silent crushing hammer, through technological innovation, achieves efficient crushing while significantly reducing noise and vibration. This enables its application scope to expand from traditional fields to modern engineering that has higher requirements for the environment, safety and precision.

Email: [email protected]

LICH has accumulated many years of rich design concepts and experience. The silent models designed by them feature smooth lines and adopt the latest enclosed shell protection design for the main unit and MIC vibration reduction technology to reduce noise. From municipal construction to mining operations, LICH’s silent series products can meet the various needs of a wide range of users. With powerful impact force and excellent crushing performance, they can adapt to harsh environmental conditions and have occupied an important position in the foreign mining industry due to their high efficiency, stability and durability. They have created a powerful myth for large-scale machinery.

.-1.png)

Hydraulic breaker hammers have become an important operation tool for hydraulic excavators. Some people also install hydraulic breaker hammers on backhoe loaders (also known as dual-action loaders) or wheeled loaders for crushing operations.

Powerful and highly efficient

Easy to connect

You can easily adjust the hydraulic flow and pressure. When using tools from other brands, only simple manual adjustments are required.

Optimization points

To enhance flexibility, we offer various types of pick heads with different designs for the hydraulic breaker, as well as pads.

Bucket list

Suitable for wide buckets, standard buckets and narrow buckets.

| Parameter | Value |

| Overall Length with Silencer | 3783 mm |

| Total Weight with Silencer | 4575 kg |

| Drill Rod Diameter | 175 mm |

| Working Flow Rate | 220–270 L/min |

| Set Pressure | 280 bar |

| Working Pressure | 230–250 bar |

| Rear Cylinder Air Pressure | 25–28 bar |

| Accumulator Air Pressure | 55–60 bar |

| Impact Frequency | 130–200 bpm |

| Hose Size | 1 1/4 inch |

| Drill Rod Length | 1500 mm |

| Compatible Host Machine Weight Range | 40–50 t |

This is the most classic and urgently demanded application field for silent impact hammers.

Broken concrete walls, foundations and steel structures: In urban renewal and factory renovation projects, partial or complete demolition of existing building structures is carried out. The silent characteristics ensure the normal life of surrounding residents, the low vibration protects adjacent structures and underground pipelines, and the accuracy facilitates the recovery of steel bars.

Removal or maintenance of highway bridges: When conducting partial repairs (such as on damaged bridge decks or piers) on busy traffic arteries or elevated bridges, it is necessary to minimize the vibration impact on the traffic flow and the overall structure of the bridge. Silent breaker hammers are the preferred choice.

Tunnel and subway excavation: Breaking down rocks and concrete in the extension sections or tunnels of already operational subway stations. In confined spaces, noise is amplified, and extremely high vibration control requirements are imposed on the existing lining structure. Noise-reducing equipment is indispensable.

Pile head driving and pavement removal: During the construction of building foundations, level the concrete pile heads that exceed the designed elevation; or remove the old pavement layers. In densely constructed areas, reduce interference among equipment.

After the initial blasting, carry out safe and efficient secondary processing.

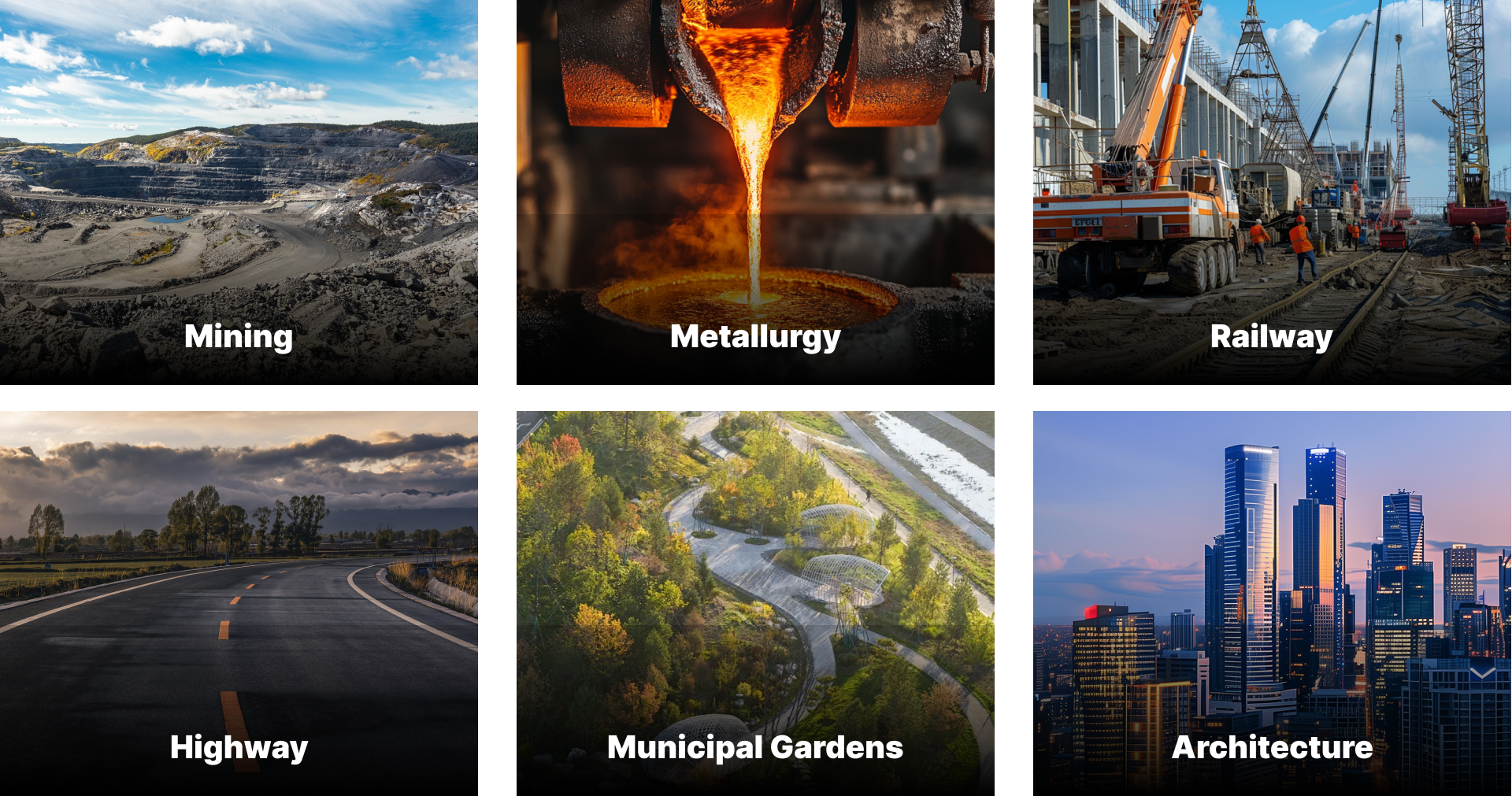

Secondary crushing of rocks and ores / Crushing of oversized stones and boulders: Breaking down the irregular large chunks of rock produced after blasting into sizes suitable for transportation and entry into the crushing machine. The silent design has improved the working environment for the front-line miners, reducing noise-induced occupational diseases.

Open-pit mining and underground mining operations: In underground mines, noise and vibration issues are more prominent. Low-noise equipment can improve communication and enhance safety; when the open-pit mine is close to the community, it helps meet environmental protection requirements.

This involves a large number of “minimally invasive surgeries” for the city, and the impact on citizens’ lives needs to be minimized.

Removal of asphalt and concrete during road reconstruction: During the “white-to-black” transformation or renovation of urban roads, the old pavement layers are quickly removed, while minimizing the noise impact of the construction on the surrounding shops and residents.

Excavation of pipelines and cable trenches: When laying or repairing underground water, electricity, gas, communication pipelines, precise excavation must be carried out beside the existing facilities. The low vibration characteristic ensures that the existing pipelines are not damaged, thereby ensuring the safety of the construction.

Sanitary sewer, drainage and public utility infrastructure projects: During deep pit excavation or hard ground fracturing in residential areas, minimize disturbance to the foundations of surrounding houses and reduce noise complaints.

In a natural environment, achieve harmony among people, equipment and the environment.

Land clearing and site preparation / Removing rocks from farmland and mountain paths: Clearing large boulders and solitary rocks within the site to create conditions for landscaping or farming. The silent feature reduces disturbance to wildlife habitats, which is particularly important in rural tourism areas.

Tree stumps and broken roots: Instead of using traditional excavators to forcefully pull them out, this method can crush the underground tree stumps and root systems on-site. It is highly efficient and does not damage the surrounding landscape plants and terrain. It is a commonly used technique in high-end garden projects.

It serves the circular economy and is a crucial part of “green demolition”.

Concrete and debris recycling / Reduction of waste size during demolition / Secondary crushing of aggregates: At the construction waste resource processing site, large pieces of demolition materials (such as beams and columns) are crushed into smaller sizes to facilitate subsequent sorting and recycling. The silent impact crusher can effectively control the secondary pollution of dust and noise during the crushing process, meeting the standards of an environmentally friendly workshop.

Demonstrate the outstanding reliability and adaptability of the equipment.

Continuous operation in high-intensity or dusty environments: Its design usually places greater emphasis on sealing and heat dissipation, enabling stable operation in dusty and poorly ventilated tunnels, with a long maintenance interval.

Crushing of frozen and hard soil: For seasonal construction or in high-altitude areas, powerful hydraulic power can effectively break through the frozen and hard soil layers, creating conditions for excavation operations.

High-temperature or remote working environments: For instance, in steel mills during dismantling operations or in remote mining areas, equipment must have excellent heat resistance and reliability. The optimized design of silent impact hammers often enables better handling of these challenges.

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A : A silent impact crusher is a new type of hydraulic crushing equipment that significantly reduces noise and vibration through optimized design (such as using an enclosure, hydraulic buffering, high-frequency micro-vibration, etc.). The key difference lies in:

Noise: The working noise can be reduced by 20-30 decibels compared to traditional hammers, and is usually below 100 decibels, which is more in line with environmental protection requirements.

Vibration: The vibration transmitted to the excavator body and the ground is significantly reduced, protecting the equipment, infrastructure and operators.

Design: Usually, a closed enclosure is adopted, which also has the functions of noise reduction, dust prevention and splash protection.

A : The main technologies include:

Soundproof housing: The interior is lined with sound-absorbing materials, enclosing the impact components.

Buffer system: A hydraulic or rubber buffer device is placed between the impact piston and the cylinder to soften the impact.

Energy guidance: Optimizing the path of impact energy transmission to reduce ineffective vibrations. High-frequency low-amplitude mode: Some models offer a “precision” mode with high frequency and small amplitude, resulting in lower noise.

A : Urban sensitive areas: Residential areas, hospitals, schools, commercial centers – for building demolition and renovation.

Restricted projects: Underground railway construction, tunnel work, around historical buildings, projects requiring night construction permits.

Fine operations: Pile head treatment, indoor demolition, separation and recycling of structural components. Special environments: mines with high dust levels, factory workshops sensitive to vibration, emergency rescue operations.

A : Initial investment: Yes, due to its complex design and noise-reducing materials, the purchase price is usually 30% to 50% higher than that of traditional hammers, and even more in some cases.

Total holding cost: However, in the long run, since it can reduce equipment wear and tear, avoid environmental fines, and expand high-value business, the return on investment (ROI) may be higher.

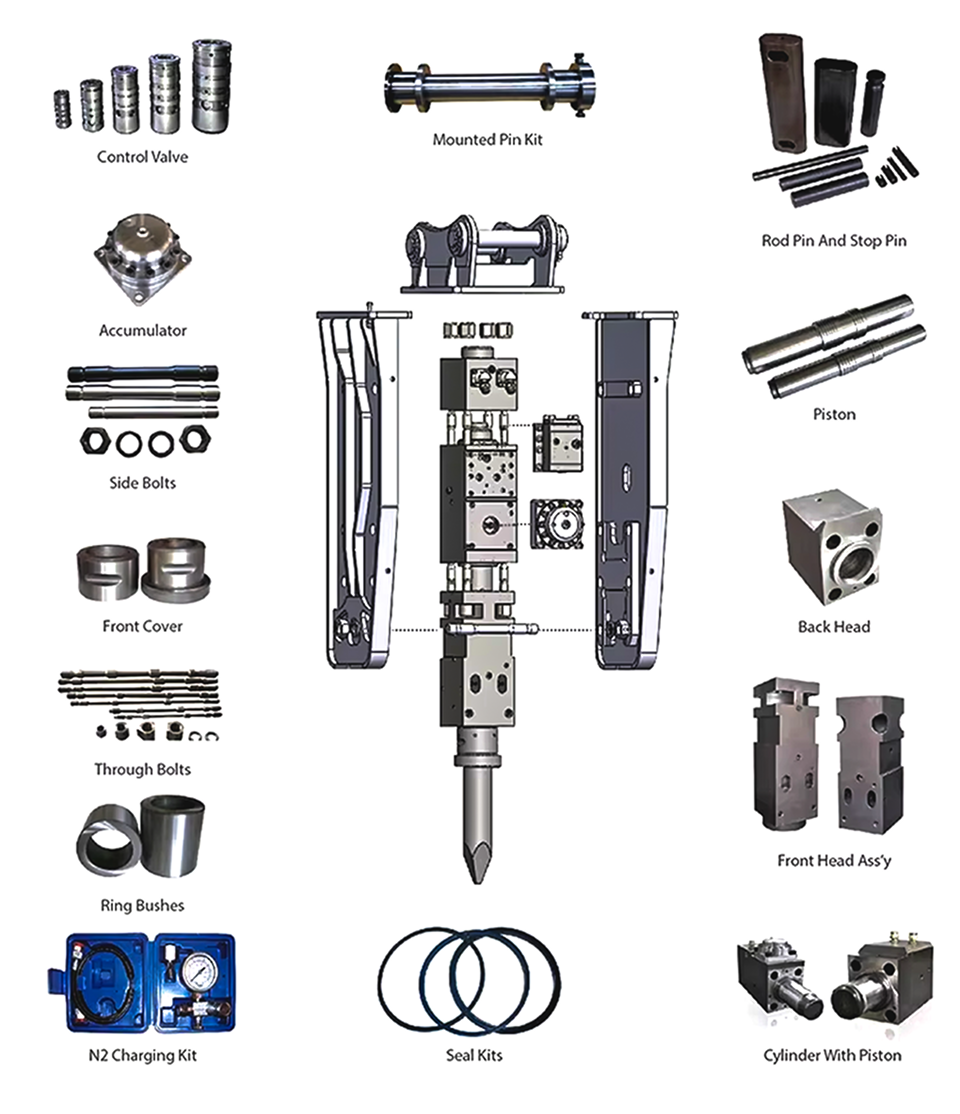

Maintenance: The maintenance process is similar to that of traditional hammers, but the outer shell and internal cushioning components may require specific care. Choosing a reputable brand with timely supply of accessories is crucial.

Contact With Us

If you have any questions please fell free to contact with us.