The LC388 front-mounted backhoe excavator is a highly efficient and versatile construction machinery that integrates loading and excavation functions. Its "one machine, two uses" design enables it to quickly switch between various construction scenarios such as construction, agriculture, roads, and mining. By replacing various attachments (such as multi-functional buckets), it can flexibly meet different operation requirements, making it an ideal choice for achieving efficient operations and economic practicality.

Email: [email protected]

The LC388 front-mounted backhoe loader is a highly efficient model in the “Excavator Loader” (commonly known as “Busy on Both Ends”) series. It innovatively integrates the front-end loader and the rear-end backhoe excavator into one unit, achieving “one machine for two purposes”, making it an ideal solution for various complex operation scenarios.

It is equipped with various auxiliary tools and can perform a wide range of operations such as excavation, loading and dumping, road crushing, site leveling, trenching and channel digging, pipeline laying, etc. It is widely used in agricultural water conservancy, construction, municipal sanitation, road maintenance and repair, postal and telecommunications, and other types of engineering projects.

Front-end loader: Equipped with a large-capacity bucket, it is proficient in material loading, transportation, lifting and site leveling operations.

Backhoe excavator: Equipped with a powerful digging arm, it specializes in downward digging, trenching, foundation pit rectification, and precise earthwork operations.

This unique design enables the operator to simply rotate the seat in the cab and quickly switch between the two systems, seamlessly transitioning between different processes.

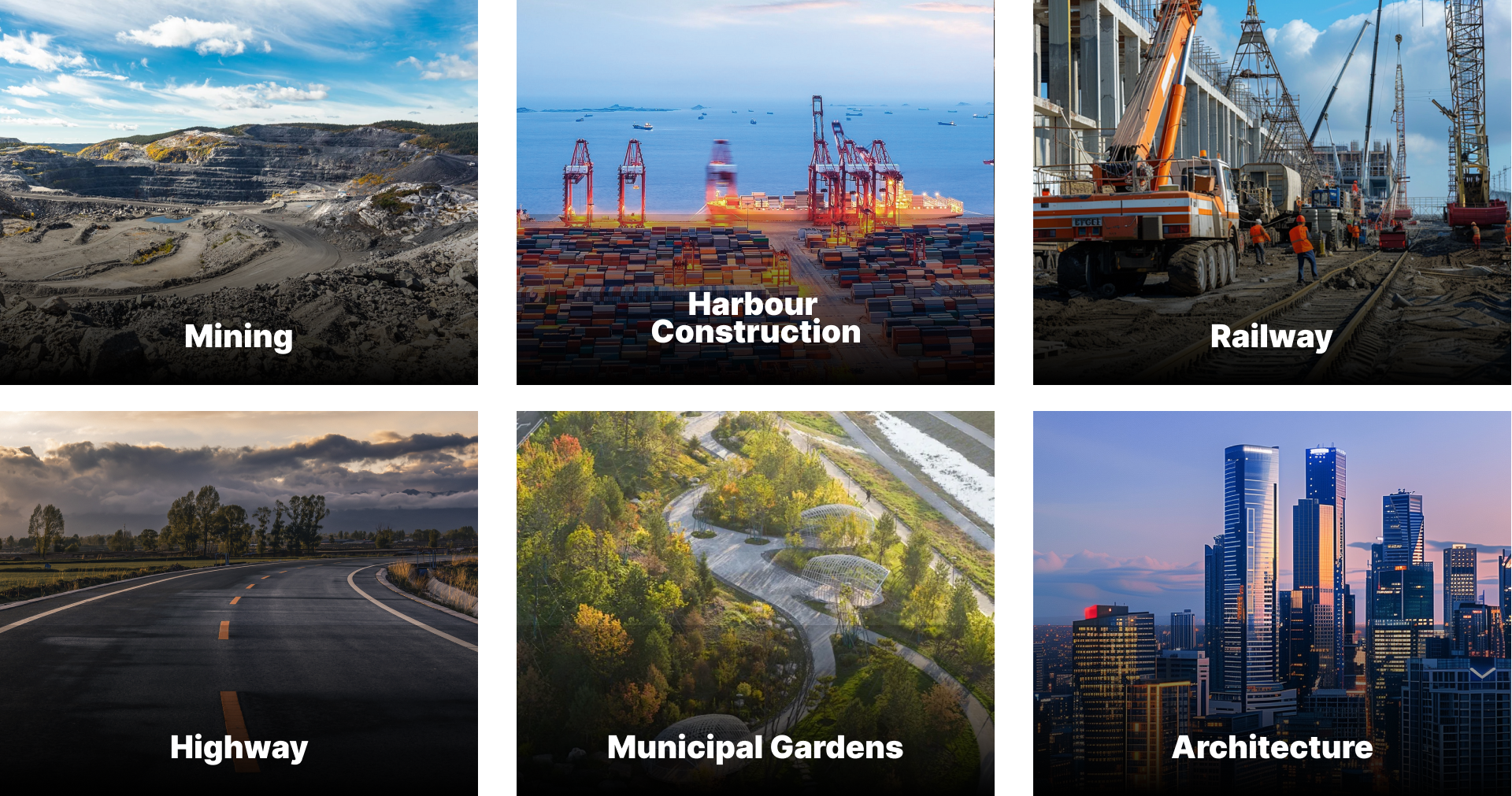

As you mentioned, this device, thanks to its versatility, has been widely applied in:

Construction project: Site leveling, foundation pit excavation, material transportation and backfilling.

| Product Parameters | |||

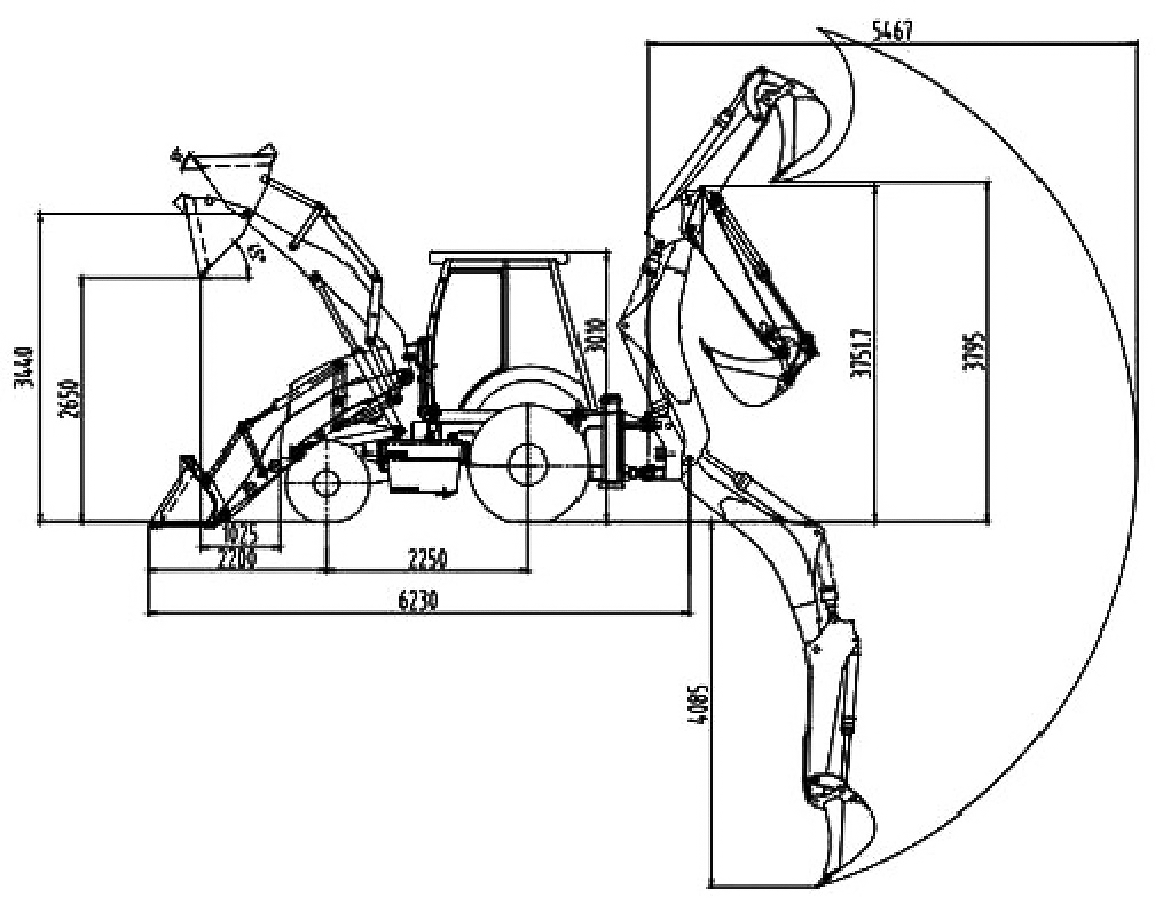

| Total operating weight | 8200kg | L*W*H | 6230x2365x3752 |

| Wheel base | 2280mm | Min. ground clearance | 300mm |

| Loader | |||

| Bucket capacity | 1.2 m³ | Breakout force | 39KN |

| Loading lifting capacity | 2500kg | Bucket dump height | 2650mm |

| Bucket dump reach | 1025mm | Digging depth | 52mm |

| Backhoe | |||

| Backhoe capacity | 0.3 m³/750kg | Max. digging depth | 4082mm |

| Swing angle of excavator bucket | 190° | Max. pulling force | 39KN |

| Engine brand | Weichai | Engine model | YC4A105Z-T20 |

| Type | Direct injection, four-stroke | Rated power | 75kw |

| Steering system | Full hydraulic | Min. turning radius | 6581mm |

| Drive type | 4-wheel drive | System pressure | 12Mpa |

| Drive axle | Carraro Italy | Torque converter | YJ280 |

| Gearbox type | Fixed shaft power transmission | Tires | 14-17.5/19.5I-24 |

The integral frame,provides excellent stability and is more suitable for excavation work.

The excavating working device is side shift type,high strength and good structural stability; the loading end working device adopts eight-bar linkage mechanism.

A loader is a type of earthwork construction machinery that is widely used in various construction projects (such as highways, railways, construction works, hydropower projects, ports and mining projects).

This is the most traditional and primary application area for loaders.

Site leveling and cleaning: Remove debris from the surface, backfill or transport earth materials.

Material handling and loading/unloading: Loading and unloading of construction materials such as bricks, sand and gravel, cement, and wood.

Auxiliary tasks: Supply materials to the mixing station, clean construction waste, and transport materials over short distances.

Foundation excavation: Carry out light excavation and backfilling of the foundation pit.

In mines and quarries, large and super-large wheeled loaders are the main equipment.

Open-pit mining: Working in coordination with excavators and mining trucks, this position is responsible for loading the blasted minerals or earth and rock onto transportation vehicles.

Material storage management: Conducting the stacking, retrieval and loading operations of materials in the storage yard.

Mine road maintenance: Used for building and maintaining roads within the mining area.

Road/Railway Construction: Fill the roadbed, transport subgrade materials (such as crushed stones and stabilized soil), and clean the construction site.

Municipal engineering: Used for pipeline laying, trench backfilling, asphalt material transportation (requires a special hot material bucket).

Port/airport construction: Conduct extensive foundation treatment and material transportation.

Agricultural production: Transporting fertilizers, grains (such as wheat), straw, cleaning livestock sheds, participating in the construction of farmland water conservancy facilities (such as digging ditches).

Wood industry: Handling and transporting logs and timber at forest farms and wood processing plants (often equipped with log grabbers).

Water conservancy project: Used for earthwork operations during river dredging and dam reinforcement.

Port Terminals: At bulk cargo terminals, various bulk commodities such as coal, minerals, and grains are loaded and unloaded.

Logistics center and factory: Handling finished products, raw materials and waste materials, conducting site cleaning and organization.

Steel and metallurgy enterprises: Handling high-temperature or heavy materials such as ores, coke, and steel slag (using special buckets).

Waste disposal and recycling: Materials are piled up, loaded and sorted at landfill sites and recycling centers for renewable resources.

Winter snow removal: After installing snow pushers or snow shovels, they are used to clear snow from plazas, roads and airports.

Disaster relief: After floods and earthquakes, it is used to remove silt, debris and obstacles, and to clear paths for rescue operations.

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A : It is mainly used for scooping, transporting, and unloading various loose materials such as sand, gravel, and coal. It can also perform light-level leveling and earth-moving operations.

A : The core function of a loader is to move materials on the ground; while the core function of an excavator is to dig downward.

A : Work scale: For large-scale operations, select the larger tonnage (over 6 tons); for general purposes, choose the medium-sized one (3-5 tons).

Main materials: The heavier and harder the materials, the greater the power required.

Tool requirements: Frequent use of various tools such as forks and clamps, so a quick-change device should be selected.

A : Multi-functional bucket: It integrates clamping, bulldozing and leveling functions.

Wood-grabbing device/Side-discharge bucket: Suitable for forestry and narrow spaces.

Snow-pushing plate/Sweeping device: Used for snow removal and cleaning.

A : It is mainly used in all industries that require the transportation and movement of loose materials, such as construction, mining, ports, agriculture, logistics, and municipal services.

Contact With Us

If you have any questions please fell free to contact with us.