A bulldozer is an earthmoving machinery capable of excavating, transporting and discharging rock and soil. It is widely used in open pit mines. For example, it is used to build earth dumps, level vehicle dumps, accumulate scattered mineral rocks, level work flats and construction sites, etc. It is not only used for auxiliary work, but also for main mining work. For example: stripping and mining of sand deposits, traction and boosting of scrapers and rock plows, cooperating with other earthmoving machinery to reduce the height of the stripping step when there is no transportation mining method.

Email: [email protected]

LICHMACH LC320 Bulldozer is a large-power bulldozer produced using the most advanced domestic manufacturing technology for standard mass production.

The entire machine adopts advanced hydraulic transmission and hydraulic control technology. The structure is advanced and reasonable, with easy and flexible operation and reliable quality.

The powerful NT855-C360S10 diesel engine can deliver an output power of up to 235 kilowatts (320 horsepower). The engine power is smoothly transmitted to the final drive unit through efficient torque.

The standard straight-edge inclined blade has a powerful cutting force and can handle various harsh working conditions; the large single-handle loosening tool has an adjustable penetration angle and can be used to loosen clay and frozen soil, as well as to remove hard working surfaces such as gravel and hardened salt mines.

The highly reliable power-shift transmission, stable hydraulic torque converter and two-stage positive gear final drive system have a high power transmission efficiency.

The full-box type main frame, made of high-performance materials and high-strength castings, has a high capacity for resisting impact loads and bending moments. The high-quality welding ensures the service life of the main frame. The semi-rigid suspension walking system increases the contact area of the tracks, enhancing the vehicle’s traction.

Bulldozers can be divided into two types: crawler type and tire type. The crawler bulldozer has large adhesion and traction, small ground specific pressure (0.04 to 0.13MPa), and strong climbing ability, but its driving speed is low. The tire-type bulldozer has high driving speed, flexible maneuverability, short operation cycle time, and convenient transportation and transfer. However, it has small traction force and is suitable for situations where construction sites and field work need to be frequently changed.

It can be divided into two types: general type and special type. The universal type is a model produced according to standards and is widely used in earthworks. Special-purpose bulldozers are used under specific working conditions, including wetland bulldozers and swamp bulldozers that use triangular wide track shoes to reduce ground contact pressure, amphibious bulldozers, underwater bulldozers, cabin bulldozers, unmanned bulldozers, plateau prototypes, and high-altitude bulldozers. Bulldozers operating in wet conditions, etc.

◆ The appearance of the vehicle is based on optimization design

◆ Higher engine power reserves efficiency ,bigger torque output ,lower fuel consumption ,while better reliability

◆ Hydraulic controlled drive,automatically speed regulation and non-stop gear shifting

◆ 3-element,single stage,single phase torque converter for higher efficiency and bigger capacity

◆ The novel hexahedral cad offers excellent visibility, the powerful ventliation and unparalleled dust-free.

◆ The final drive uses triangle Spline and tip lelief, crowned gear drive to enhance the balance and the stability of the load of transmission part

◆ New blade is more durable and capacious

◆ Alarming monitoring system is efficient and reliable

◆ Implement controls are piloted to minimize operating effort

| Model | GTY320 |

| Type | Standard Hydraulic Crawler Type |

| Engine Model | CUMMINS NTA855-C360S10 |

| Engine Displacement (L) | 14.01 |

| Rated Power (kW/rpm) | 257/2000 |

| Max. Torque (N.m/rpm) | 1400/1440 |

| Operating Weight | 37.2 Ton |

| Dimension (without ripper) (L*W*H mm) | 6880×4130×3688 |

| Grounding Length (mm) | 3150 |

| Ground Pressure (MPa) | 0.105 |

| Track Gauge (mm) | 2140 |

| Dozing Capacity (m³) | 10 |

| Blade width(mm) | 4130 |

| Blade height(mm) | 1590 |

| Max drop below ground(mm) | 560 |

| Track shoe width(mm) | 560 |

| Pitch(mm) | 228.6 |

| Quantity of track link | 41 |

| Quantity of Carrier rollers | 4 |

| Quantity of Track rollers | 14 |

| Max pressure(MPa) | 14 |

| Discharge L/min | 355 |

| Max tractor force(KN) | 280 |

| Forward Speed (Km/h) | F1:0-3.6 |

| F2:0-6.6 | |

| F3:0-11.5 | |

| Rear Speed (Km/h) | R1:0-4.4 |

| R2:0-7.8 | |

| R3:0-13.5 |

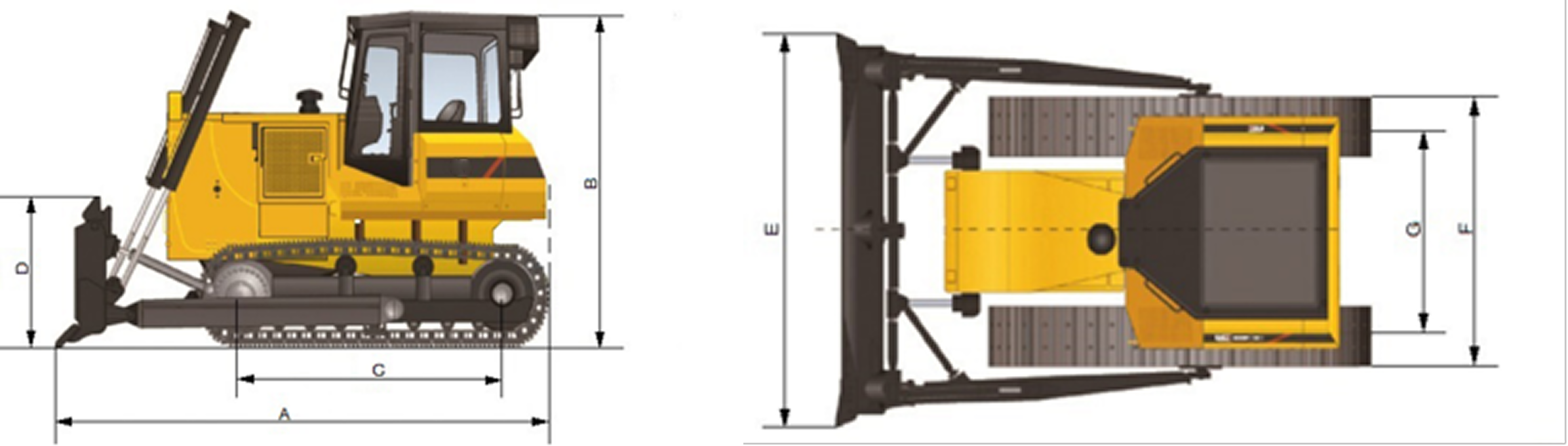

| DIMENSIONS | |

| A Overall Length | 6,590 mm |

| B Height to Top of Cab | 3,910 mm |

| C Track Length on Ground | 3,150 mm |

| D Blade Height | 1,530 mm |

| E Blade Width | 4,130 mm |

| F Width over Track | 2,700 mm |

| G Track Gauge | 2,140 mm |

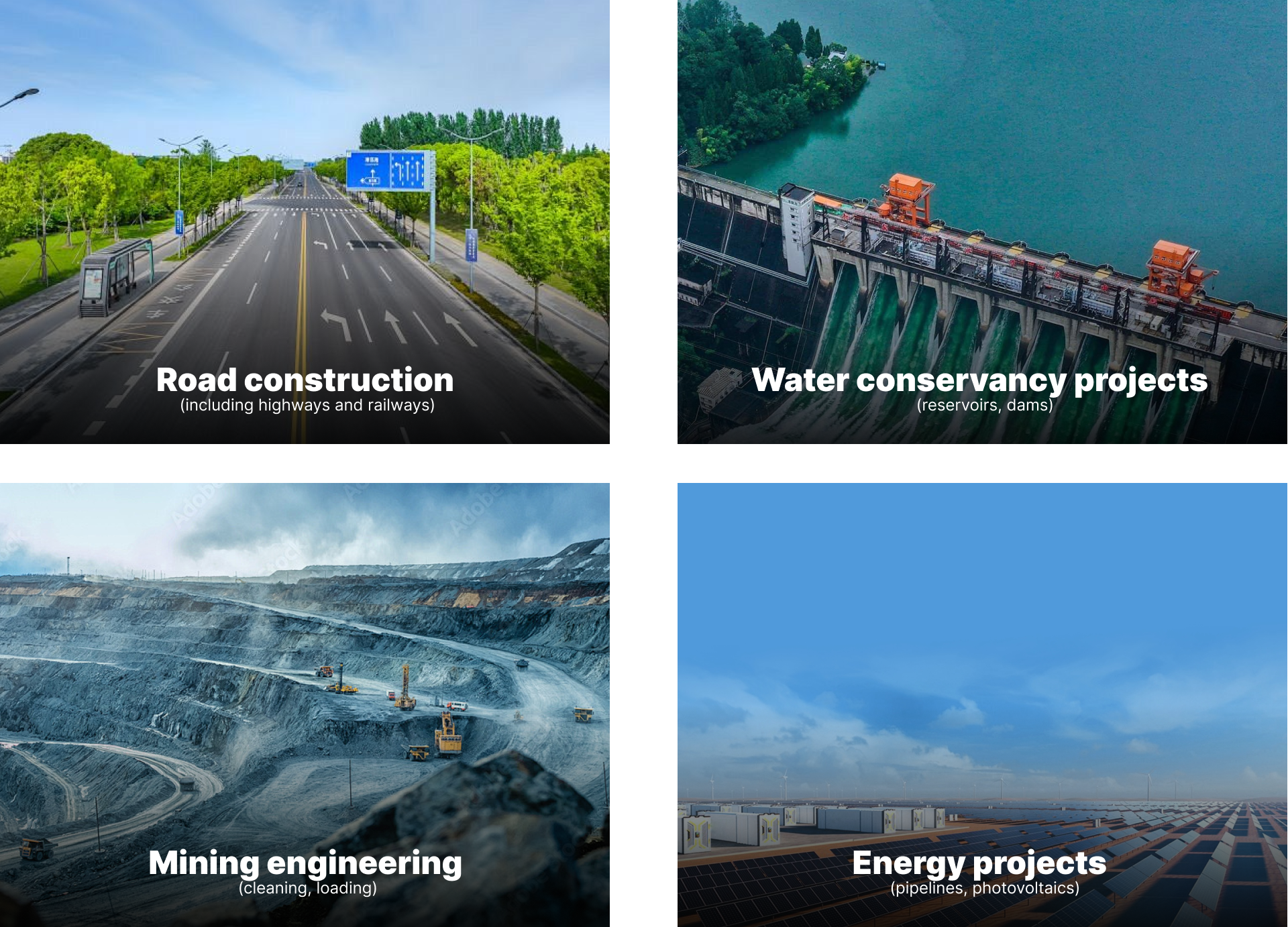

Involves large-scale longitudinal movement of earth, precise leveling and high-intensity compaction.

Excavation and clearing: Remove vegetation, topsoil and obstacles within the construction area.

Subgrade filling and paving: Bulldozers push the excavated soil from the excavation site or cut section onto the subgrade in layers.

Fine leveling and slope trimming: Before the bulldozer performs fine leveling, it first completes large-scale leveling. Construction and maintenance of access roads: Build and maintain construction access roads on both sides of the main line to ensure the passage of other equipment and vehicles.

The characteristics of water conservancy projects are huge earthwork volume, extremely high requirements for compaction and stability, and often carried out in humid or muddy environments.

Dam body filling: Transport the soil materials (clay, gravel soil, etc.) from the material site to the dam surface, and spread them at strict layer thicknesses (usually around 30cm). Ensure the seepage prevention and stability of the dam body.

Temporary cofferdam construction: Build temporary cofferdams in the river to create dry land construction conditions. Require rapid earth pushing into the water and compaction.

Channel excavation and shaping: Excavate the water diversion or drainage channels and precisely shape the cross-sectional shape and slope of the channels. Reservoir area and dam foundation cleaning: Remove the weak soil layers, vegetation, etc. from the bottom of the reservoir and the dam foundation.

Overburden removal: Remove the soil and rocks (overburden) above the ore body to expose the ore.

Workface cleaning and stacking: After blasting, push the scattered waste rock into piles to create conditions for the electric shovel or front-end loader to load, significantly improving the efficiency of the entire loading and transportation system.

Dump site operation: Push the waste rock to the edge of the dump site and push it down. At the same time, be responsible for leveling and compacting the dump site platform to ensure its stability.

Mining road maintenance: The leveling, repair, and snow removal of the mining truck roads are crucial, directly affecting transportation safety and efficiency.

Similar to large-scale infrastructure projects, extremely high precision in site leveling is required to ensure the construction of large equipment foundations.

Photovoltaic power station: Thousands of acres of land are precisely leveled to ensure the efficiency of the installation of photovoltaic panel supports and the subsequent power generation efficiency.

Foundation construction assistance: Leveling the foundation area.

Pipeline laying (oil and gas, water supply):

Clearing of the operation area, excavation and backfilling of the pipe trenches

● Equipment Selection Guide

● Detailed technical comparison

● One-on-one service

● One-year warranty

● Local after-sales service network, with faster response speed

● Inventory of vulnerable parts

● Remote and on-site setup and operationinstructions

● Logistics timeliness

● Ensure timely delivery

● Transport from the port to your designated destination

A: It is highly suitable for medium to large-scale earthwork projects. It is commonly seen in road/railway roadbed construction, mining stripping and material transportation, large-scale site leveling, port and wharf construction, river embankment construction, and auxiliary operations in large-scale infrastructure projects.

A: By using an electronically controlled high-pressure common rail engine and an intelligent hydraulic system, it provides powerful power while optimizing fuel efficiency. The actual fuel consumption will vary depending on the operating load, working conditions (such as the hardness of the materials, slope), and operating habits. However, under typical conditions, its fuel economy is at the leading level among its peers in the same category.

A: It’s not complicated. It is equipped with user-friendly operation handles and pedals, with a reasonable layout and moderate force feedback. The spacious cab with a wide view also helps in determining the position of the equipment and the working surface. For those with basic experience in operating construction machinery, they can get started quickly after a short period of familiarization and training.

A: It’s very convenient. Routine daily/weekly checks (such as oil level, coolant, and track tension) can be carried out independently by the operator.

A: Besides the standard blade, the following options are usually available:

Contact With Us

If you have any questions please fell free to contact with us.