The QB series pedal-operated concrete mixer, with its high production capacity, reliable mixing quality, flexible and portable characteristics, and wide applicability, serves as a reliable assistant from professional engineering to household use. It is a high-quality choice for improving work efficiency and reducing labor intensity.

Email: [email protected]

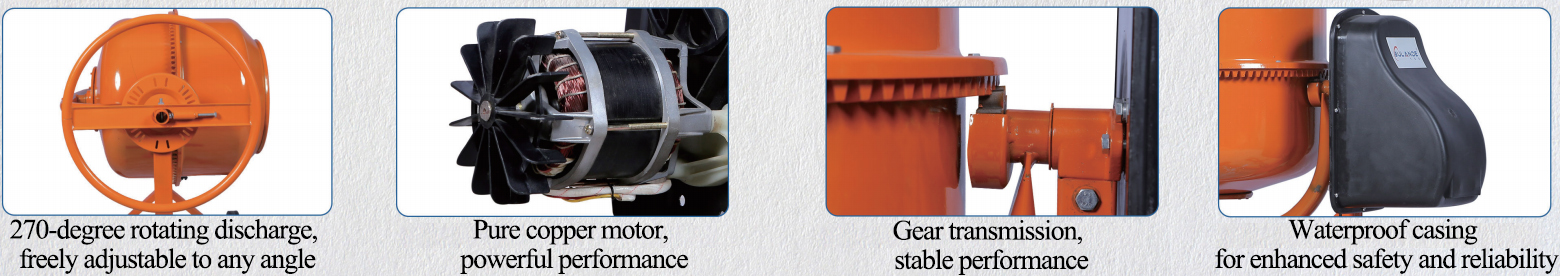

The pedal-operated concrete mixer is an ideal device designed to replace traditional manual mixing. It can easily and quickly mix sand, gravel, and water to produce a uniform and fine concrete mixture, significantly improving mixing efficiency and quality. The equipment features a rational design, compact structure, convenient operation, and reliable performance, making it particularly suitable for small and medium-sized construction projects, family farms, and various DIY projects.

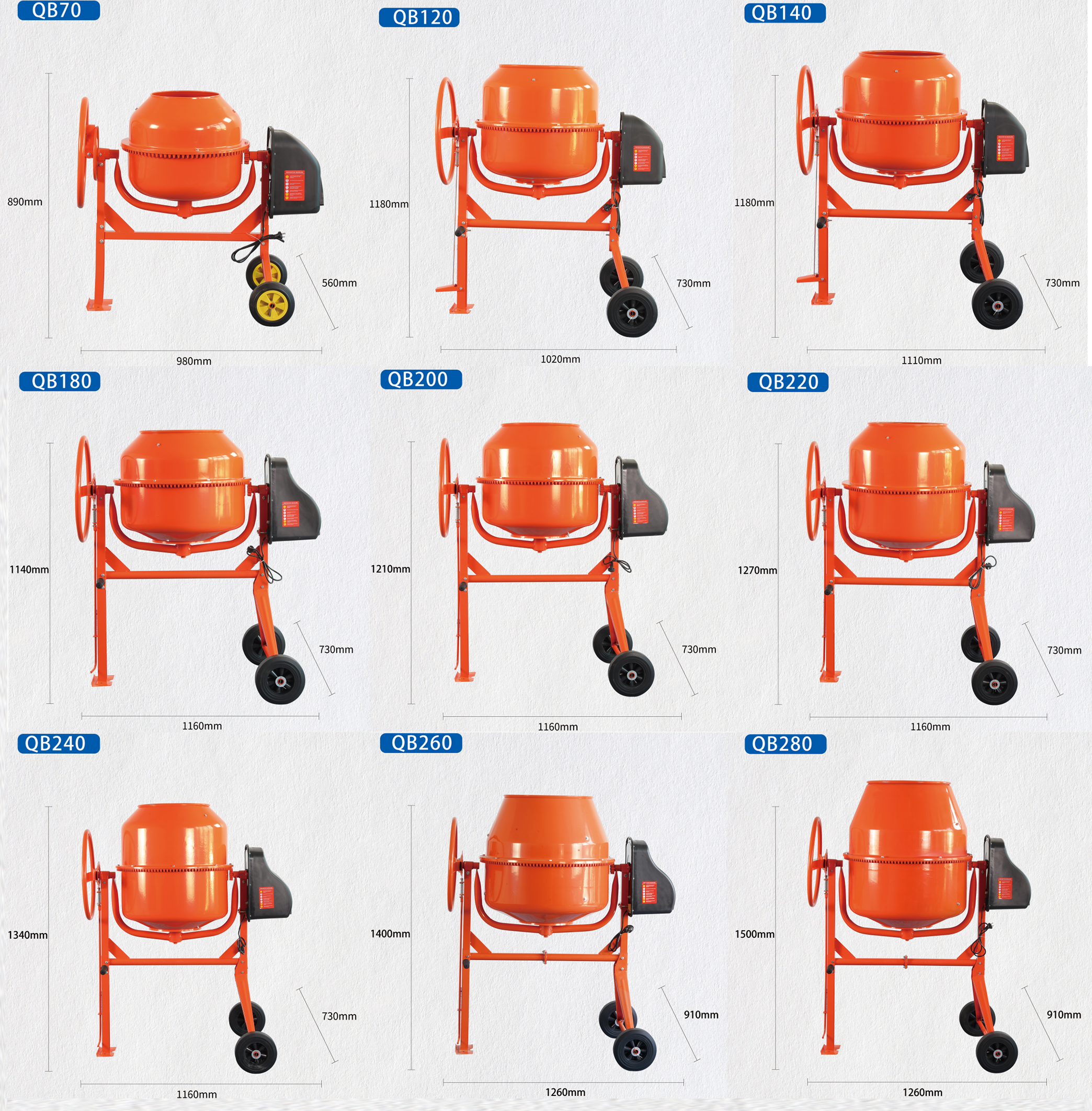

| Model | Capacity (L) | Mixing Speed (r/min) | Motor Power (W) | Weight (kg) Gross/Tare | Machine Dimensions (mm) L×W×H | Drum Diameter (mm) | Drum Height (mm) | Upper Drum Thickness (mm) | Lower Drum Thickness (mm) | Drum Opening Diameter (mm) | Carton Specifications (mm) L×W×H |

| QB70L | 60 | 30 | 350 | 37/34 | 1020×730×1180 | 510 | 580 | 1.5 | 1.7 | 460 | 710×540×350 |

| QB120L | 105 | 29 | 550 | 48/44 | 1110×730×1180 | 570 | 570 | 1.7 | 1.7 | 510 | 710×600×450 |

| QB140L | 120 | 29 | 550 | 53/49 | 1160×730×1140 | 610 | 540 | 1.7 | 2 | 580 | 730×650×450 |

| QB180L | 153 | 28 | 850 | 56/51 | 1160×730×1210 | 610 | 580 | 1.7 | 2 | 410 | 770×700×450 |

| QB200L | 170 | 28 | 1000 | 59/54 | 1160×730×1270 | 610 | 640 | 1.7 | 2 | 410 | 770×700×450 |

| QB220L | 187 | 28 | 1000 | 61/56 | 1160×730×1340 | 610 | 710 | 1.7 | 2 | 410 | 770×700×510 |

| QB240L | 205 | 28 | 1000 | 63/58 | 1160×730×1400 | 610 | 700 | 1.7 | 2.2 | 430 | 820×750×500 |

| QB260L | 240 | 28 | 1200 | 74/69 | 1260×910×1500 | 680 | 800 | 2 | 2.2 | 430 | 820×750×550 |

| QB280L | 260 | 28 | 1500 | 75/70 | 1260×910×1500 | 680 | 800 | 2 | 2.2 | 430 | 820×750×500 |

| Model | QB350L |

| Mixing Capacity | 280 L |

| Output | 4 – 5 m³/h |

| Weight | 245 kg |

| Drum Thickness | 3 mm |

| Drum Diameter | 800 mm |

| Drum Height | 800 mm |

| Power (Gasoline Version) | 5.5 HP |

| Power (Electric Version) | 3.0 kW |

| Power (Diesel Version) | 5.5 HP |

| Machine Dimensions (L×W×H) | 800 × 1050 × 1100 mm |

| Carton Specifications (L×W×H) | 1800 × 900 × 1100 mm |

Contact With Us

If you have any questions please fell free to contact with us.