Axial milling machine integrates core advantages such as high efficiency, precision, safety, environmental friendliness, and flexibility. It is not just an excavation tool but an advanced construction solution that can significantly improve project quality, reduce comprehensive costs, and create greater value for customers.Choose our longitudinal milling machine to step into a new era of intelligent and refined construction.

Email: [email protected]

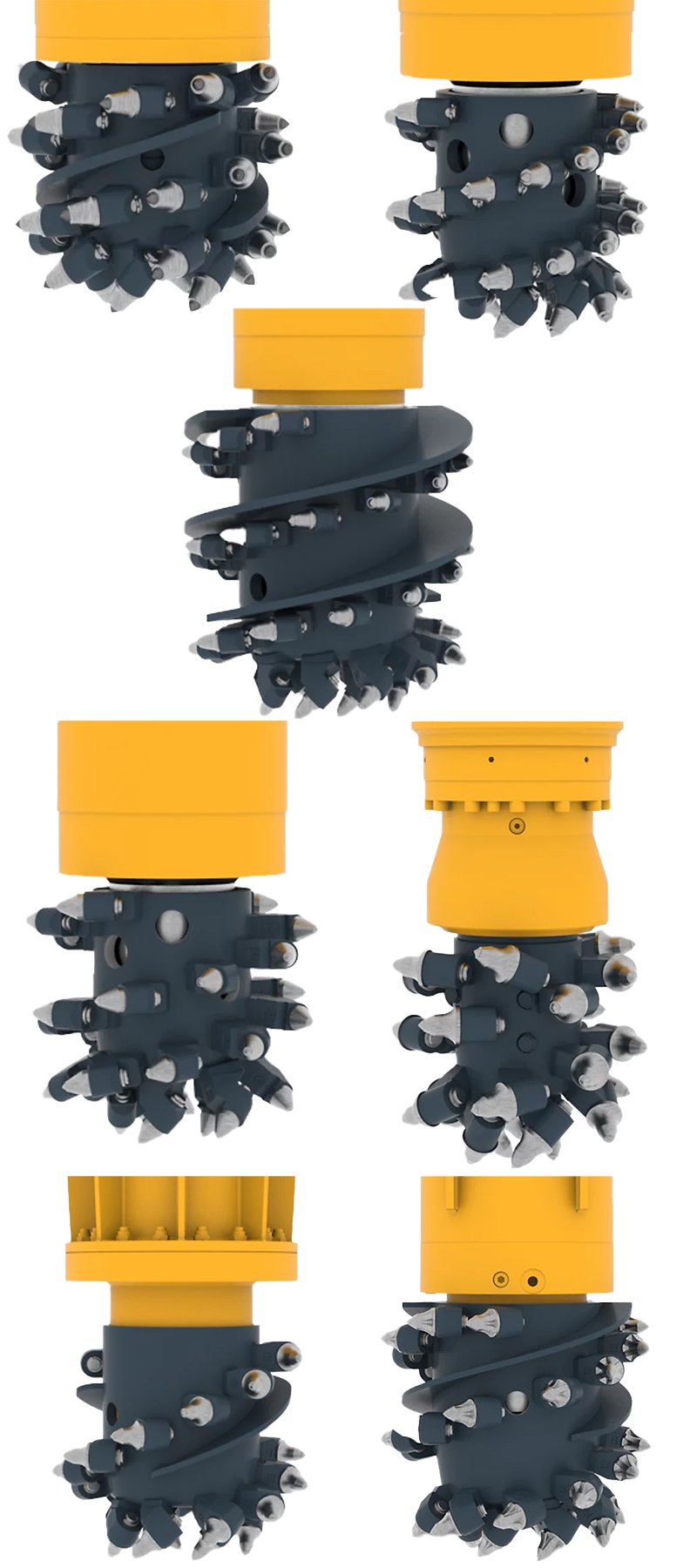

The longitudinal milling machine, also known as the vertical milling machine or trench milling machine, is a professional model specializing in longitudinal drilling, trenching, and finishing narrow channels. The rotation axis of its cutter head is basically parallel to the direction of the mechanical arm, achieving precise, efficient, and low-impact linear milling operations. It perfectly overcomes the limitations of traditional blasting and impact excavation in terms of precision, safety, and environmental protection, making it one of the core equipments for modern refined construction.

| Product Model | ER 100L | ER 250L | ER 400L | ER 450L | ER 600L | ER 700L | ERL 1100 | ER 1500L | ER 2000L |

| Compatible Equipment | 3-7t (6,600-15,400 lb) Excavator | 8-15t (17,600-33,000 lb) Excavator | 12-17t (26,500-37,500 lb) Excavator | 12-17t (26,500-37,500 lb) Excavator | 15-22t (33,000-48,500 lb) Excavator | 15-25t (33,000-55,100 lb) Excavator | 25-35t (55,100-77,100 lb) Excavator | 20-40t (44,000-88,000 lb) Excavator | 35-50t (77,200-110,200 lb) Excavator |

| Carrier Weight Class | 3 t – 7 t | 8 t – 15 t | 12 t – 17 t | 12 t – 17 t | 15 t – 22 t | 15 t – 25 t | 25 t – 35 t | 20 t – 40 t | 35 t – 50 t |

| Weight (Self) | 250 kg | 410 kg | 440 kg | 450 kg | 660 kg | 700 kg | 900 kg | 1,450 kg | 1,800 kg |

| Product Weight | 210 kg | 340 kg | 365 kg | 375 kg | 580 kg | 600 kg | 660 kg | 1,200 kg | 1,500 kg |

| Optimal Oil Flow | 52 L/min – 62 L/min | 60 L/min – 85 L/min | 120 L/min – 150 L/min | 120 L/min – 150 L/min | 120 L/min – 150 L/min | 160 L/min – 160 L/min* | 240 L/min – 300 L/min | 200 L/min – 300 L/min | 300 L/min – 390 L/min |

| Rated Power | 30 kW | 45 kW | 65 kW | 65 kW | 65 kW | 70 kW | 120 kW | 120 kW | 160 kW |

| Rotation Speed | 110 rpm | 90 rpm | 80 rpm | 80 rpm | 80 rpm | 75 rpm | 75 rpm | 75 rpm | 65 rpm |

| Max. Torque (@350 bar) | 3,120 Nm | 5,200 Nm | 10,400 Nm | 10,400 Nm | 10,400 Nm | 11,700 Nm | 23,400 Nm | 23,400 Nm | 33,500 Nm |

| Max. Cutting Force (@350 bar) | 16,900 N | 26,000 N | 52,000 N | 46,200 N | 38,900 N | 52,000 N | 93,600 N | 68,800 N | 93,000 N |

| Tool Holder Diameter | 20 mm | 20 mm | 20 mm | 22 mm | 22 mm | 22 mm | 30 mm | 30 mm | 30 mm |

| Number of Tools | 32 | 40 | 40 | 30 | 42 | 30 | 26 | 24 | 28 |

Contact With Us

If you have any questions please fell free to contact with us.