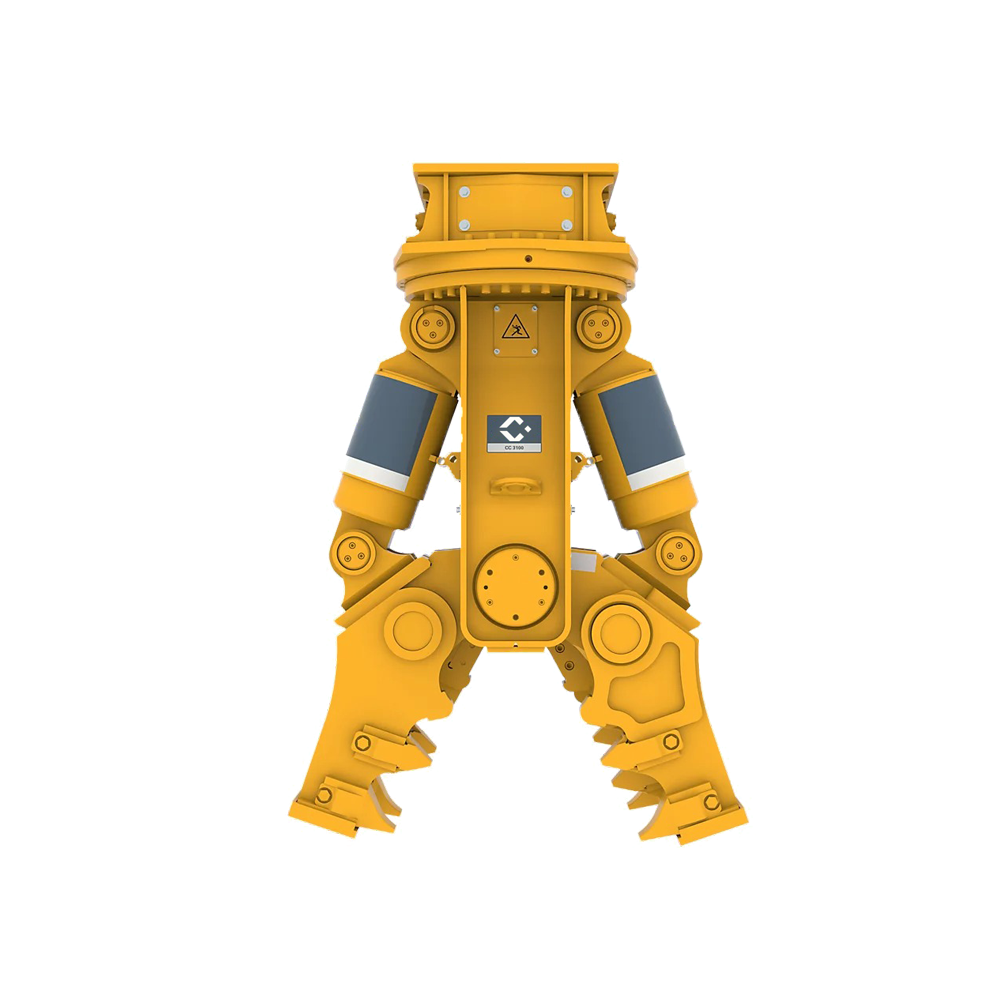

With its modular design, powerful crushing force, outstanding flexibility, and stability, the multi-functional hydraulic crusher is the ideal choice for tackling complex demolition challenges. It not only helps users save time and reduce costs but also expands the equipment's application range, making it a key asset for enhancing worksite productivity.

Email: [email protected]

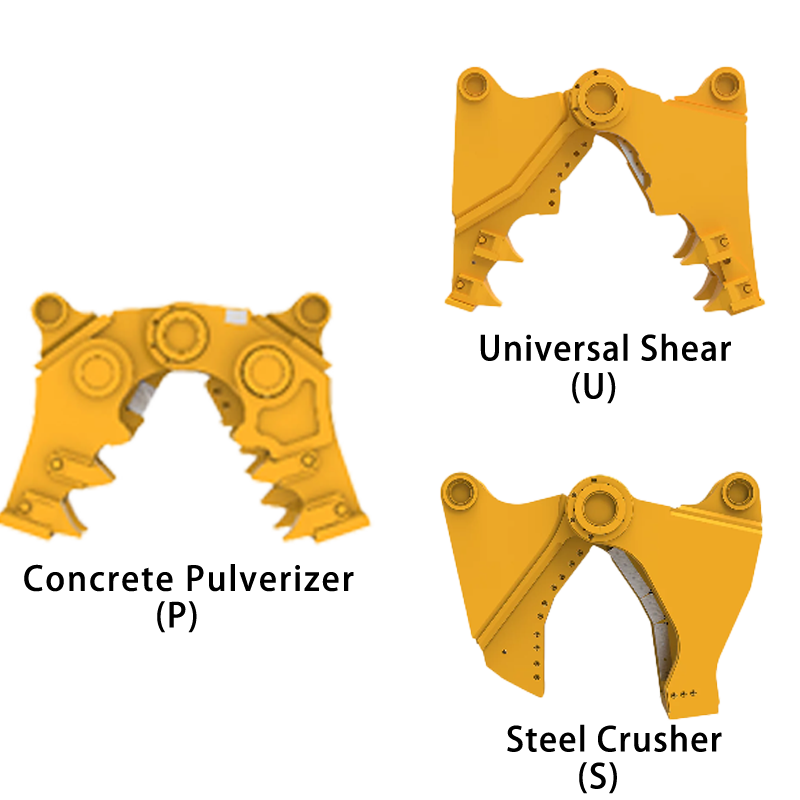

The hydraulic crusher is a high-performance equipment specifically designed for modern demolition, scrap recycling, and construction breaking operations. It features an innovative modular jaw system that allows for quick changing of different jaws, enabling efficient processing of various materials such as rock, concrete, steel, and cables. It provides an excellent solution for both primary demolition of large structures and secondary breaking at smaller work sites.

This product is suitable for use with various models of hydraulic crusher carriers, ensuring broad equipment compatibility.

| Model | CC 1600(U) | CC 2300(U) | CC 3100(U) | CC 3700(U) | CC 5000(U) | CC 7000(U) |

| Carrier Weight Class | 13t-23t | 20t-30t | 25t-40t | 30t-50t | 45t-65t | 58t-85t |

| Open Circuit Cycle Time | 1.3 s | 1.7 s | 3.1 s | 3.0 s | 3.7 s | 3.7 s |

| Closed Circuit Cycle Time | 1.3 s | 1.6 s | 2.9 s | 2.8 s | 3.2 s | 3.7 s |

| Oil Flow (Main) | 150-250 L/min | 150-250 L/min | 0-250 L/min* | 220-350 L/min | 350-450 L/min | 450-550 L/min* |

| Working Pressure (Main) | 350 bar | 350 bar | 350 bar | 350 bar | 350 bar | 350 bar |

| Oil Flow (Rotation) | 35-50 L/min | 35-50 L/min | 5-50 L/min* | 35-50 L/min | 45-50 L/min | 45-50 L/min |

| Self Weight | 1625 kg | 2290 kg | 3130 kg | 3720 kg | 5300 kg | 7100 kg |

| Product Weight | 1454 kg | 2080 kg | 2860 kg | 3420 kg | 4850 kg | 6450 kg |

| Jaw Opening | 700 mm | 750 mm | 870 mm | 1000 mm | 1300 mm | 1400 mm |

| Jaw Depth | 490 mm | 660 mm | 700 mm | 765 mm | 1090 mm | 1150 mm |

| Blade Length | 350 mm | 350 mm | 350 mm | 525 mm | 525 mm | 525 mm |

| Cutting Force (Jaw Tip) | 197 t | 257 t | 430 t | 510 t | 620 t | 830 t |

| Crushing Force (Jaw Tip) | 57 t | 70 t | 104 t | 126 t | 155 t | 180 t |

| Model | CC 1600(S) | CC 2300(S) | CC 3100(S) | CC 3700(S) | CC 5000(S) | CC 7000(S) |

| Carrier Weight Class | 13t-23t | 20t-30t | 25t-40t | 30t-50t | 45t-65t | 58t-85t |

| Open Circuit Cycle Time | 1.3 s | 1.7 s | 3.1 s | 3.0 s | 3.7 s | 3.7 s |

| Closed Circuit Cycle Time | 1.3 s | 1.6 s | 2.9 s | 2.8 s | 3.2 s | 3.7 s |

| Oil Flow (Main) | 150-250 L/min | 150-250 L/min | 0-250 L/min* | 220-350 L/min | 350-450 L/min | 450-550 L/min* |

| Working Pressure (Main) | 350 bar | 350 bar | 350 bar | 350 bar | 350 bar | 350 bar |

| Oil Flow (Rotation) | 35-50 L/min | 35-50 L/min | 5-50 L/min* | 35-50 L/min | 45-50 L/min | 45-50 L/min |

| Max. Operating Pressure (Rotation) | 170 bar | 170 bar | 170 bar | 170 bar | 115 bar | 115 bar |

| Self Weight | 1550 kg | 2160 kg | 3865 kg | 3400 kg | 4960 kg | 6750 kg |

| Product Weight | 1350 kg | 1950 kg | 2635 kg | 3100 kg | 4510 kg | 6000 kg |

| Shear Jaw Opening | 380 mm | 415 mm | 400 mm | 440 mm | 720 mm | 750 mm |

| Jaw Depth | 385 mm | 485 mm | 465 mm | 625 mm | 865 mm | 900 mm |

| Blade Length | 380 mm | 380 mm | 380 mm | 525 mm | 875 mm | 875 mm |

| Cutting Force (Jaw Tip) | 197 t | 294 t | 430 t | 510 t | 620 t | 830 t |

| Crushing Force (Jaw Tip) | 61 t | 87 t | 145 t | 147 t | 198 t | 205 t |

| Model | CC 1600(P) | CC 2300(P) | CC 3100(P) | CC 3700(P) |

| Carrier Weight Class | 13t-23t | 20t-30t | 25t-40t | 30t-50t |

| Open Circuit Cycle Time | 1.3 s | 1.7 s | 3.1 s | 3.0 s |

| Closed Circuit Cycle Time | 1.3 s | 1.6 s | 2.9 s | 2.8 s |

| Oil Flow (Main) | 150-250 L/min | 150-250 L/min | 0-250 L/min* | 220-350 L/min |

| Working Pressure (Main) | 350 bar | 350 bar | 350 bar | 350 bar |

| Oil Flow (Rotation) | 35-50 L/min | 35-50 L/min | 5-50 L/min* | 35-50 L/min |

| Max. Operating Pressure (Rotation) | 170 bar | 170 bar | 170 bar | 170 bar |

| Self Weight | 2070 kg | 2670 kg | 3500 kg | 4300 kg |

| Product Weight | 1870 kg | 2460 kg | 3265 kg | 4000 kg |

| Shear Jaw Opening | 830 mm | 747 mm | 832 mm | 960 mm |

| Jaw Depth | 540 mm | 605 mm | 643 mm | 692 mm |

| Blade Length | 140 mm | 140 mm | 140 mm | 190 mm |

| Cutting Force (Jaw Tip) | 197 t | 264 t | 430 t | 510 t |

| Crushing Force (Jaw Tip) | 54 t | 71 t | 112 t | 129 t |

Contact With Us

If you have any questions please fell free to contact with us.